ASME B16.50-2021 pdf free download.Wrought Copper and Copper Alloy Braze-Joint Pressure Fittings

4.3 ð21Þ Definitions out-of-roundness: maximum measured diameter minus the minimum measured diameter. ovality: elliptical condition associated with out-of-round- ness. wrought: describing metal that is worked in solid form to form shapes or individual parts including but not limited to tubular shapes, bars, and forgings.

5 MARKING Each fitting shall be permanently marked with the manufacturer’s name or trademark in accordance with MSS SP-25 and the letters “BZ” in uppercase. Marking on fittings less than size 1 ∕ 2 or on any fitting where it would damage the brazing surfaces is not required.

6 ð21Þ MATERIAL

(a) FittingsshallbemadefromcopperUNSNo.C10200, C12000, or C12200 or copper alloy UNS No. C23000, for which allowable stresses are found in ASME B31.1, ASME B31.9,orASMEBoilerandPressureVesselCode,SectionII, Part D.

(b) Other coppers and copper alloys are permitted, provided (1) they meet the chemical requirements of 80% minimum copper and 16% maximum zinc (2) the fittings produced from the copper alloy meet all the mechanical and corrosion-resistant properties for the end purposes of the fittings Thecompositionofthecopperalloys shallcontainnothing that will inhibit joining to the tube or to other fittings.

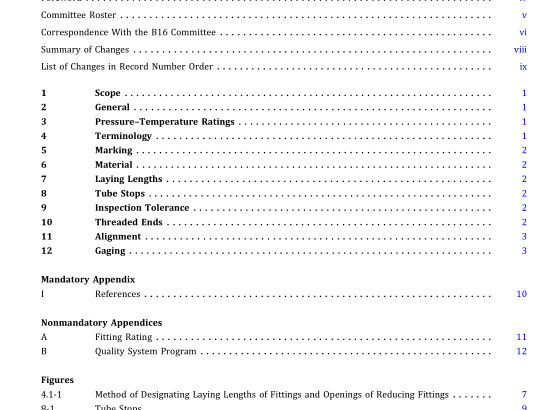

7 LAYING LENGTHS Due to widely varying manufacturing processes, meaningful laying length requirements of fittings cannot be established. Consult the manufacturer for these dimensions.

8 TUBE STOPS Except for repair couplings, fittings shall be manufac- turedwithatubestop. Repaircouplings shallnotrequirea tube stop. The tube stop shall control joint length, even with an external (FTG) end having the minimum outside diameter shown in Table 3.1-1. Examples ofvarious tube stop configurations are shown in Figure 8-1.

9 INSPECTION TOLERANCE

9.1 Convention For determining conformance with this Standard, the convention for fixing significant digits where limits (maximum and minimum values) are specified shall be as defined in ASTM E29. This requires that an observed orcalculatedvalueberoundedofftothenearestunitinthe last right-hand digit used for expressing the limit. Decimal values and tolerances do notimplya particular method of measurement.

9.2 Linear Dimensions An inspection tolerance, as shown in Table 9.2-1, shall be allowed on center-to-shoulder, center-to-center, center-to-threadedend, and shoulder-to-threaded-end dimensions on all fittings having internal (C) braze ends, as well as on center-to-braze-end and braze-end- to-threaded-enddimensionsonallfittingshavingexternal (FTG) braze ends. Couplinginspection limits forshoulder- to-shoulder and shoulder-to-end dimensions shall be double those shown in Table 9.2-1, except that the minus tolerance applied to dimension L (Figure 4.1-1) shall not result in a dimension less than 1.5 mm (0.06 in.). The largest opening in the fitting shall govern the tolerance to be applied to all openings.

9.3 Ovality of Fitting End (C or FTG) Maximum ovality ofthe fitting braze-jointend shall not exceed 1% of the maximum diameters shown in Table 3.1-1. The average of the maximum and minimum diameters shall be within the dimensions shown in the table.

9.4 Inside Diameter of Fitting The minimum cross-sectional area of the inside diameter through the fitting body shall not be less than the theoretical minimum area defined by diameter O in Table 3.1-1. The out-of-roundness condition of the cross-sectional area shall not exceed the value shown in Table 3.1-1. For reducer or adapter fittings, the smallest end diameter shall apply, provided that this diameter does not restrict the other outlets.

9.5 Wall Thickness The minimum wall thickness shall not be less than shown in Table 3.1-1. 10 THREADED ENDS Fittingthreads shall be righthand, conformingto ASME B1.20.1. They shall be taper threads (NPT).ASME B16.50 pdf download.ASME B16.50-2021 pdf free download