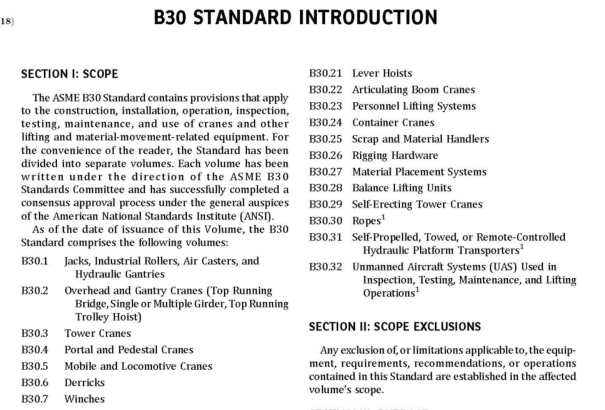

ASME B30.2-2018 pdf free download.Self-Erecting Tower Cranes 5afety 5tandard for Cableways , Cranes , Derricks , Hoists , Hooks , Jacks , and 51 ings

SECTION 29-0.1: SCOPE OF B30.29

Volume B30.29 includes provisions that apply to theconstruction,operation, inspection, testing, and mainte-nance of powered self-erecting tower cranes thatadjust operating radius by means of a trolley traversinga jib. These may be horizontal, elevated, articulating, ortelescoping, and used for vertical lifting and lowering offreely suspended, unguided loads that consist of equip-ment and materials.

Self-erecting tower cranes have vertical or nearlyvertical masts that are bottom slewing and mountedon fixed, traveling, or mobile bases.The cranes arecapable of moving or being moved from job site to jobsite fully assembled or nearly fully assembled.

This Volume does not apply to cranes used for nonver-tical lift ing service or lifting a guided load, or to truck-mounted material delivery cranes with a tubular boomand trolley traversing the boom.Tower cranes (referto ASME B30.3) and mobile crane tower attachments(refer to ASME B30.5) are not within the scope of thisVolume.

SECTION 29-o.2: DEFINITIONS

29-0.2.1 Types of Self-Erecting Tower CranesSee Figures 29-0.2.1-1 and 29-0.2.1-2.

29-0.2.2 General

accessory: a secondary part or assembly of parts thatcontributes to the overall function and usefulness of amachine.

administrative or regulatory authority: governmentalagency, or the employer in the absence of governmentaljurisdiction.

axis of rotation: the vertical line about which a craneswings.

axle: the shaft or spindle with which or about which awheel rotates. On wheel-mounted cranes, it refers to atype of axle assembly including housings, gearing, differ-ential, bearings, and mounting appurtenances.

balanced: the condition of the superstructure of a self-erecting crane necessary for telescoping the mast;theload is positioned at that radius that causes the vertical moment of the superstructure about the balance point togo to zero.

ballast: weights added to the fixed frame to create addi-tional stability or to counter the effects of the lifted load.bogie: the assembly that includes a pivot,frame, axle(s),and wheel(s) on which a crane rides on rails, and includesan assembly oftwo or more axles arranged to permit bothvertical wheel displacement and an equalization ofloading on the wheels.

brake: a device other than a motor used for retarding orstopping motion by friction or power means.

braking means: a method or device for retarding or stop-ping motion.

buffer: an energy-absorbing device for reducing impactwhen a moving crane or trolley reaches the end of itspermitted travel.

cab: a housing provided for the operator and containingthe crane controls.

control station: the location ofthe crane function controls,either cab-mounted or by remote control.

counterweight: weights added to the rotating frame tocreate additional stability or to counter the effects ofthe lifted load.

crane: in this Volume, the use ofthe word “crane” refers toself-erecting cranes, which are lifting machines, mountedon a base, with a superstructure consisting of a mast,rotating frame, and a jib.

crossover points: points of rope contact where one layer ofrope on a rope drum crosses over the previous layer.direct supervision: adesignated operator in the immediatearea of the trainee, within visual sighting distance,andable to effectively communicate with the trainee. Thedesignatedoperator shall have no duties other than obser-ving the operation of the crane by the trainee.

dismantle: to fold/retract and disassemble crane forremoval or relocation.

dog everything: apply or engage all brakes, locks, andpawls.

drum: the cylindrical member around which rope iswound; used for multiple functions on the crane.

ensure: the term used when the meaning “take stepsto seethat” or “make sure” is intended.

equalizer: a device that compensates for unequal length oftwo or more supporting components.

erection: assembly, setup, and initial configuration of thecrane.

flange point: the point of contact between the rope anddrum flange where the rope changes layers on a ropedrum.

hoist mechanism: a hoist drum and rope reeving system;used for one or more functions on the crane.

in-service: the condition of a crane ready for or engaged inwork; an operator is at the controls.

jib: the structural member attached to the mast of a craneon which the trolley travels when changing load radius.job site: area within the boundaries of the project wherethe crane is to be operated.ASME B30.2 pdf download.ASME B30.2-2018 pdf free download