ASME B31T-2021 pdf free download.Standard Toughness Requirements for Piping ASME Code for Pressure Piping, B31

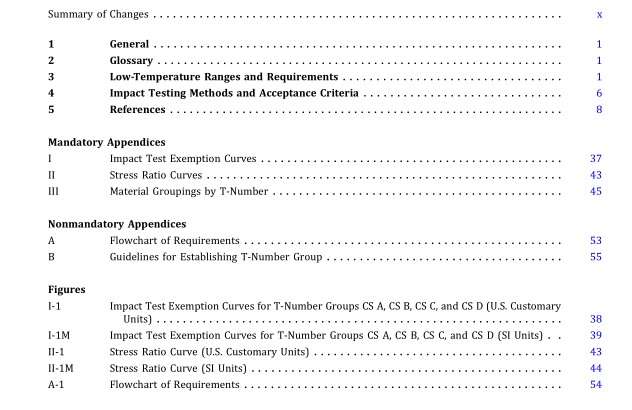

3.3 ð21Þ Governing Thickness and Notes (Columns 2 and 3 of Table 3.1-1) For T-number groups in which the low-temperature suitability varies significantly according to the material thickness, a governing thickness is listed in column 2 of Table 3.1-1 at various low-temperature service limit increments. When it is desired to refine the influence of the governing thickness, Mandatory Appendix I provides the continuous curves and tables that can be used at intermediate values or greater governing thick- nesses. Since the governing thicknesses in Table I-1 of Mandatory Appendix I are generally derived based on uniform increments of temperature, the table does not contain uniform increments of governing thickness. The continuous curves in Figures I-1 and I-1M in Mandatory Appendix I should be consulted for the precise values. For material T-number groups in which the low- temperature suitability is dependent on some other factor, those factors are given in the notes listed in column 3 of Table 3.1-1.

3.4 ð21Þ Low-Temperature Service Limit (Column 4 of Table 3.1-1) Column4,thefirsttemperaturecolumninTable3.1-1,is the low-temperature service limit. Ifthe design minimum temperature is equal to or warmer than this value, then low-temperature requirements do not apply. Materials withina T-numbergroup maybe used atthis temperature ortemperatures warmer than this limitwithoutimposing any of the requirements of this Standard. This limit considers material properties and the influence of fabri- cation processes on the material properties.

3.5 ð21Þ Material Requirements for Low-Temperature Service (Columns 5 and 6 of Table 3.1-1) Column 5 lists the minimum permitted temperature of the material. When a temperature is listed, this is the design minimum temperature permitted for the T- number group regardless of impact testing or any other requirements except as permitted by column 18, wheretheappliedstressislimitedto30%oftheallowable.

Column 6 contains the minimum temperature without impact testing for the material. If the design minimum temperature is equal to or warmer than this value, the material does not require impact testing. If the design minimum temperature is colder than this value, impact testing of the material is required. For carbon steels, this limit may vary with governing thickness or stress ratio. Additional rows are provided in Table 3.1-1 for governing thickness variations. Interpolation between governing thicknesses is permitted. Figures and a table for the curves of the variation of temperature with governing thickness are provided in Mandatory Appendix I, and these may be used as an alternative to the values in Table 3.1-1. Permitted temperatures for stress ratios are provided for by using columns 10 through 18 instead ofcolumn 6 as discussed in para.

3.6. 3.6 Design Requirements for Low-Temperature Service (Columns 10 Through 18ofTable 3.1-1) 3.6.1 Minimum Material Temperature Without Impact Testing. Columns 10 through 17 list the minimum material temperature without impact testing based on design stresses and may be used for carbon steels provided (a) the piping system is subjected to a hydrostatic test at no less than 1.5 times the design pressure (b) the piping system is not subjected to unevaluated external loads such as maintenance loads, impact loads, and thermal shock The curve used to generate columns 10 through 17 in Table 3.1-1 is provided in MandatoryAppendixII andmay be used as an alternative to columns 10 through 17. Column 18 lists the minimum low-temperature service limitachievablebylimitingstressestolessthan10%ofthe tensilestrength[i.e.,thestressratio (SR) ≤ 0.3] andmaybe used without any additional low-temperature service re- quirements. At these stress levels, the design margin is considered adequate to prevent a brittle fracture failure mode. The low-temperature service limit listed in column 18 may be used in lieu of that listed in column 4 when SR ≤ 0.3.

3.6.2 Stress Ratio. The stress ratio is defined as the maximum of the following:

(a) nominal pressure stress (based on minimum pipe wall thickness less allowances) divided by the allowable stress at the design minimum temperature.

(b) for piping components with pressure ratings, the pressure for the condition under consideration divided by the pressure rating at the design minimum temperature.

(c) combined longitudinal stress due to pressure, dead weight, and displacement strain (stress intensification factors are not included in this calculation) divided by the allowable stress at the design minimum temperature. In calculating longitudinal stress, the forces and moments in the piping system shall be calculated using nominal dimensions, and the stresses shall be calculated using section properties based on the nominal dimensions less corrosion, erosion, and mechanical allowances. In determining the stress ratio, the loadings coincident with the metal temperature under consideration may be used in lieu of maximum design values. Where there are several low-temperature design conditions, each shall be evaluated to determine the stress ratio.ASME B31T pdf download.ASME B31T-2021 pdf free download