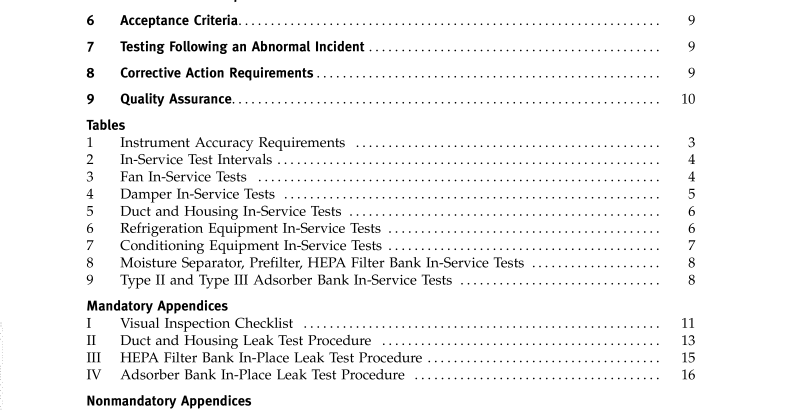

ASME N511-2007 pdf free download.In-Service Testing of Nuclear Air Treatment, Heating, Ventilating, and Air-Conditioning Systems

3 GENERAL INSPECTION AND TEST REQUIREMENTS All inspections and tests shall be conducted in accor- dance with the requirements within this Standard and the specific requirements of sections 6 and 8. Activities discussed in this Standard may involve the use of hazardous materials, operations, and equipment. This Stan- dard does not purport to address all of the safety requirements associated with their use. The owner’s test program shall establish appropriate safety and health practices and determine the applicability of regulatory requirements.

3.1 Test Instruments A calibration program shall be established in accor- dance with ASME NQA-1 requirements. All permanent and temporary test instruments used in the conduct of tests required by this Standard shall be in calibration. Instrument accuracy shall meet or exceed the requirements of Table 1.

3.1.1 Range Requirements. The full-scale range of instruments shall be limited as necessary to ensure that the readings are within the accuracy requirements of Table 1.

3.1.2 Instrument Fluctuation. Symmetrical damp- ing devices or averaging techniques may be used to reduce random signal fluctuations. Hydraulic instru- ments may be damped by using gage snubbers or throttling valves in instrument lines.

3.1.3 Evaluation Following Test Instrument Loss, Damage, or Calibration Failure. When a test instrument is lost, damaged, or otherwise fails to meet the requirements of Table 1 during calibration, all test results obtained using the instrument shall be evaluated, dating backto the time ofthe previous calibration. Ifthe evalua- tion does notconfirm that the instrumentmetthe accept- ance criteria for the test(s) in question, the test(s) shall be repeated with calibrated instruments.

3.1.4 Specific Instrument Accuracy Requirements 3.1.4.1 Vibration Instrument. Vibration instru- ment accuracy shall be at least ±10%. The minimum frequency response range of the vibration-measuring instrument shall be approximately one-third ofthe mini- mum shaft speed. For rotating components, the maxi- mum frequency response range shall be at least two times the rotational shaft speed of the component being measured. For reciprocating components, the maximum frequency response range shall be at least two times the speed of the rotating element, times the number of unique planes occupied by a piston throw.

3.1.4.2 Challenge Aerosol-Measuring Instrument. The challenge aerosolmeasuring instrument shall be verified to have a linear range of at least 10 5 times the minimum detectable quantity of the instrument.

3.1.4.3 Challenge Gas-Measuring Instrument. The challenge gas-measuring instrument shall be verified to be capable of distinguishing challenge gas from back- ground and measuring challenge gas over a linear range of at least 10 5 times the minimum detectable quantity of the instrument.

3.2 Reference Values

3.2.1 Establishment of Reference Values. Reference values are determined during acceptance testing (ASME AG-1, Article TA-4000), when the equipment or system 3 is proven to be operating within the acceptable limits of the design specification. Operating tests and inspections specified in ASME AG-1, Article TA-4000 are performed under conditions readily reproducible during subse- quent in-service tests to allow for direct comparison of test results. All test results and associated analyses are included in the test procedure documentation.

3.2.2 Reestablishment ofReference Values Following Component Replacement, Repair, or Modification. Fol- lowing component replacement, repair, or modification requiring disassembly, an evaluation shall be conducted to determine the effect on current reference values. Whenever the evaluation indicates any of the reference values have been affected, new reference values shall be established inaccordance withpara. 3.2.1 ortheprevious reference values reverified. Evaluation of the new reference values shall verify that the component conforms to the acceptance criteria prior to accepting it as fully operational. The evaluation to determine the effect on reference values shall be documented.ASME N511 pdf download.ASME N511-2007 pdf free download