ASME MFC-1M-2003 pdf free download.GLOSSARYOFTERMS USED IN THE MEASUREMENTOF FLUID FLOWIN PIPES

1.1 Scope This Standard consists of a collection of definitions of those terms that pertain to the measurement of fluid flow in pipes. Only those terms of general usage have been included. Terms having unique meaning when applied to specific meters should be included in a glos- sary within the specific flowmeter standard.

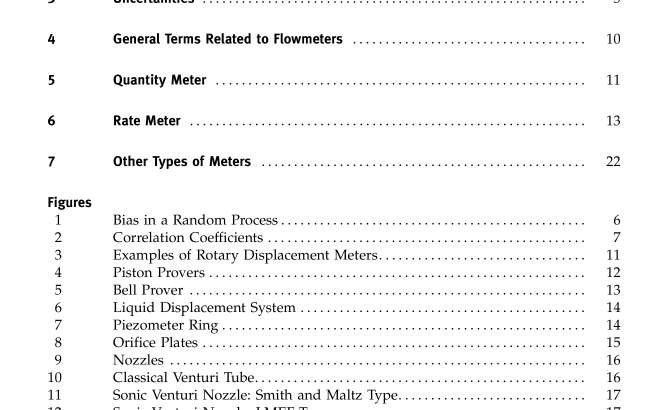

1.2 Organization This Standard is organized so that all of the terms peculiar to a particular method of fluid measurement are collected together in a separate section. Terms per- taining to basic fluid flow concepts and properties are defined in para.

1.3 References This Standard was compiled from many sources, includingvarious reportsandstandards fromTheAmer- ican Society of Mechanical Engineers (ASME), The American Gas Association (AGA), the American Petro- leum Institute (API), the Instrument Society of America (ISA), the British Standards Institute (BSI), and the Inter- national Organization for Standardization (ISO).

2. Terms pertaining to the estimate of uncertainty of a flow rate measurement are defined in para. 3. General terms applying to flowmeters are defined in para. 4. Terms relating to specific types of flowmeters are defined in paras. 5, 6, and 7. Symbols normally applied to various quantities are tabulated in Table 1.

2 GENERAL TERMS IN FLUID MECHANICS

2.1 Base Pressure A specified reference pressure to which a fluid volume at flowing conditions is reduced for the purpose of bill- ing and transfer accounting. [It is generally taken as 14.73 psia (101.560 kPa) by the gas industry inthe United States.]

2.2 Base Temperature A specified reference temperature to which a fluid volume at flowing conditions is reduced for the purpose of billing and transfer accounting. [It is generally taken as 60°F (15.56°C) by the gas industry in the United States.]

2.3 Base Volume Volume of a fluid at base pressure and temperature.

2.4 Cavitation The implosion of vapor bubbles formed after flashing when the local pressure rises above the vapor pressure of the liquid. See also flashing (para. 2.8).

2.5 Coanda Effect Effect that occurs when a jet of fluid adheres to a nearby solid surface.

2.6 Doppler Effect Apparent change in the frequency of radiation due to relative motion between a primary or secondary source and the observer.

2.7 Dynamic Pressure The increase in pressure above the static pressure that results from the complete isentropic transformation of the kinetic energy of the fluid into potential energy. It is equal to the product 1 ⁄ 2 ? v 2 , where ? is the fluid density and v is the fluid velocity.

2.8 Flashing The formation of vapor bubbles in a liquid when the local pressure falls to or below the vapor pressure of the liquid, often due to local lowering of pressure because of an increase in the liquid velocity. See also cavitation (para. 2.4).

2.9 Flow Conditioner General term used to describe any one of a variety of devices intended to reduce swirl and/or to regulate the velocity profile.

2.9.1 Flow Straightener. Flow conditioner inserted in a pipe to eliminate or reduce swirl.

2.9.2 Profile Regulator. Flow conditioner inserted in a pipe to reduce the straight length required to achieve fully developed velocity distribution.

2.10 Flow Rate The quantity of fluid flowing through a cross section of a pipe per unit of time.

2.10.1 Base Flow Rate. The flow rate calculated from flowing conditions to base conditions of pressure and temperature.

2.10.2 Mass Flow Rate, q m . The rate of flow of fluid mass through a cross section of a pipe. 2.10.3 Volume Flow Rate, q v . The rate of flow of fluid volume through a cross section of a pipe.

2.11 Gage Pressure The difference between the local absolute pressure of the fluid and the atmospheric pressure at the place of the measurement.

2.12 Hydraulic Diameter The ratio of four times the cross-sectional area of the flow to the wetted perimeter. For a filled circular pipe, the hydraulic diameter is equal to the inside diameter of the pipe. 2.13 Isentropic Exponent, ? Ratio ofthe relative variation ofpressure to the corres- ponding relative variation of mass density under ele- mentary reversible adiabatic (isentropic) transformation conditions. Often, this ratio is assumed constant over the chosen integration interval, and for an ideal gas is equal to the ratio of the specific heat capacities.ASME MFC-1M pdf download.ASME MFC-1M-2003 pdf free download