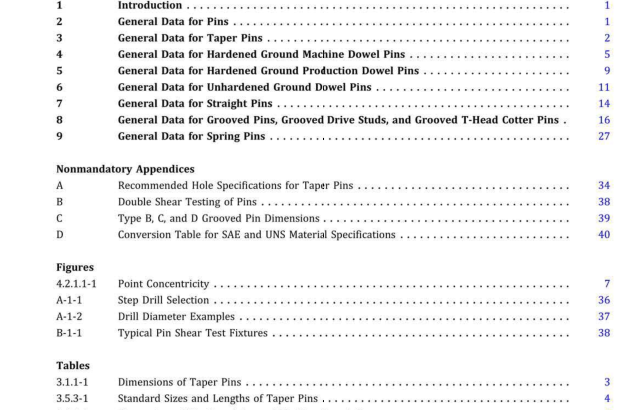

ASME B18.8.2-2020 pdf free download.Taper Pins, Dowel Pins, Straight Pins, Grooved Pins, and Spring Pins (Inch Series)

2.1.2.3 Unhardened Ground Dowel Pins. This variety of dowel pin shall have ground cylindrical sides with both ends chamfered. Dimensions are given in Table 6.1.1-1.

2.1.3 Straight Pins. Straight pins shall have unground, straight cylindrical sides with both ends definitely cham- fered on chamfered straight pins and with both ends having broken corners or being slightly chamfered on square end straight pins. Dimensions are given in Table 7.1.1-1.

2. 1.4 Grooved Pins. Grooved pins shall have unground, straight cylindrical sides with three or more swaged or extruded grooves equally spaced around the periphery to displace material beyond the basic pin diameter. Both ends of the pin are normally crowned or chamfered. Several types of grooved pins are available, including headed versions, grooved drive studs, and grooved T- head cotter pins, to satisfy various design considerations. Upon installation, the material displaced by the grooves is forced back into the grooves and reacts against the sides of the hole to promote ret ention of the pin or stud. Dimen- sions of the various types of groove pins are given in Tables 8.2.1-1 through 8.2.2-2, grooved drive studs are shown in Table 8.2.1-2, and grooved T-head cotter pins are covered in Tables 8.2.1-3 and 8.5.3-3. 2.1.5 Spring Pins. Spring pins shall have straight cylin- drical sides with both ends chamfered. They are available in two basic types, reflecting slotted construction and coiled construction, and the l atter in standard duty, heavy duty, and light duty series to suit various design requirements. Slotted-type spring pins having a single wall and coiled-type spring pins having multiple walls are formed or wrapped from strip stock to a diame ter l arger than basic and hardened in accordance with para. 9.6. Upon installation the pin diameters contract and the spring reaction against the sides of the hole tends to retain the pin . Dimensions of slotted-type spring pins and coiled-type spring pins are given in Tables 9.4.4-1 and 9.4.4-2, respectively.

3 GENERAL DATA FOR TAPER PINS

3.1 Diameters

3. 1.l Major Diameter. The major diameter, A, of both commercial and precision classes of pins, specified in Tab le 3.1 .1-1, is the diameter at the large end and is the basis for the pin size.

3.1.2 Diameter at Small End. The diameter at the small end of pins, B, is a function of the length and should be specified as a reference dimension for determining drilled hole size. (See Nonmandatory Appendix A .) It shall be computed by multiplying the nominal length of pin by the factor 0.02083 and subtracting the result from the basic pin diameter.

3.2 Ends Both ends of commercial and precision class pins shall be crowned with a spherica l radius as specified in Table 3.1.1-1.

3.3 Taper

3.3.1 Commercial Class. The taper on diameter of commercial class taper pins shall be 0.250 ± 0.006 in.jft (12.00 in.) of length.

3.3.2 Precision Clas s. The taper on diameter of preci- sion class taper pins shall be 0.250 ± 0.004 in./ft (12.00 in.) of length.

3.4 Concavity and Convexity Pins shall be straight within the following limits. Refer to the illustration in Table 3.1.1-1.

3.5 Length

3.5.1 Measurement. The length of taper pins shall be measured, parallel to the axis of pin, between the points of intersection of the crown with the diameter at the ends of the pin.

3.5.2 Tolerance on Length. The tolerance on length of taper pins shall be ±0.010 in. for both commercial and precision classes.

3.5 .3 Stand a rd Lengths . The standard sizes and lengths in which taper pins are normally available are depicted in Table 3.5.3-1. Precision class pins are not produced in size numbers 11 through 14. Where other size-length combinations may be required, manufac- turers should be consulted.

3.6 Surface Roughness The surface roughness over the length of pins shall not exceed 63 µin. ( arithmetical average) on commercial class pins nor 32 µin. (arithmetical average) on precision class pins. Refer to ASME 846.1. For pins having additive finishes, these limits shall apply prior to plating or coating. 3. 7 Materials Unless otherwise specified, taper pins shall be made from SAE 1211 steel, or cold drawn SAE 1212 or SAE 1213 steel, or equivalents, and no mechanical property requirements shall apply.ASME B18.8.2 pdf download.ASME B18.2.2-2015 pdf free download