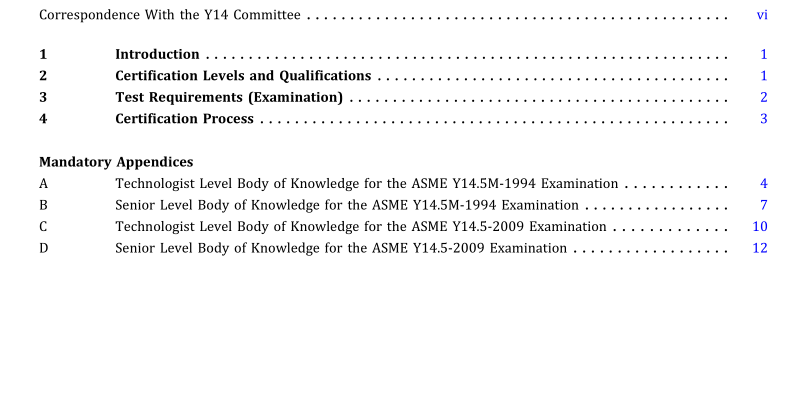

ASME Y14.5.2-2017 pdf free download.Certification of Geometric Dimensioning and Tolerancing Professionals Engineering Product Definition and Related Documentation Practices

ThisStandardprovidesrequirementsandqualifications to be used in certifying a GDTP. These requirements and qualifications recognize the knowledge, training, and experience necessary to understand, apply, and teach the principles as set forth in ASME Y14.5M-1994 or ASME Y14.5-2009. A GDTP may be employed as, but is not limited to

a) design engineer

(b) production or manufacturing engineer

(c) process engineer

(d) quality engineer

(e) tool or gage engineer

(f) engineering manager

(g) user or programmer of CAD, CAM, CAE, or other software

(h) drafter

(i) checker

(j) engineering consultant

(k) educator

(l) inspector

(m) contract engineer

(n) project engineer

(o) technical specialist

2 CERTIFICATION LEVELS AND QUALIFICATIONS

2.1 Certification Levels

There shall be two levels of GDTP certification:

(a) Technologist

(b) Senior

Certification indicates that the individual has demonstrated competence in the areas described in para.2.1.1, 2.1.2, 2.1.3, or 2.1.4.

2.1.1 Technologist Level (ASME Y14.5M-1994 Examination). Certification indicates that the individual has demonstrated an understandingofthe meaningofthe symbols,modifiers,andrelationships ofgeometricdimen- sioning and tolerancing (GD&T) as applied to engineering drawings and related documentation that conform to ASME Y14.5M-1994.

2.1.2 Technologist Level (ASME Y14.5-2009 Examination). Certification indicates that the individual has demonstrated competencies in reading and inter- preting an engineering drawing that conforms to ASME Y14.5-2009. These include, but are not limited to, the following: (a) understandingtherules,definitions,principles,and meaningsofthesymbolsandmodifiersofGD&Tasapplied to engineering drawings and related documentation (b) understanding the functions and relationships of part features and geometric controls (c) performing calculations associated with GD&T derived from the drawing and related documentation (d) understanding that the application of GD&T has implications for manufacturing, quality control, and veri- fication processes associated with engineering drawings and related documentation (e) applying the principles of GD&T to the establish- ment of functional gaging activities

2.1.3 SeniorLevel(ASMEY14.5M-1994Examination). Certification indicates that the individual has demon- strated competencies in application ofthe rules and prin- ciples required to generate an engineering drawing that conforms to ASME Y14.5M-1994. These include, but are not limited to, the following: (a) understanding the meaning of the symbols, modi- fiers, and relationships ofGD&T as applied to engineering drawings and related documentation that conform to ASME Y14.5M-1994 (b) makingthe properselection, with considerationfor thefunctionandrelationship ofpartfeatures,ofgeometric controls to document the product design intent (c) applying the appropriate geometric control symbols, modifiers, and datum references to the engi- neering drawings and related documentation (d) applyingtheprinciplesofGD&Ttotheoperationsof manufacturing, qualitycontrol, and verification processes associated with engineering drawings and related documentation (e) applying the principles of GD&T to the establish- ment of functional gaging activities

2.1.4 Senior Level (ASME Y14.5-2009 Examination). Certification indicates that the individual has demon- strated competencies in the application of the rules and principles required to generate an engineering drawing that conforms to ASME Y14.5-2009. These include, but are not limited to, the following: (a) understandingtherules,definitions,principles,and meaningsofthesymbolsandmodifiersofGD&Tasapplied to engineering drawings and related documentation (b) making the proper selection with consideration for the function and relationship of part features and geometriccontrols,to documenttheproductdesignintent (c) performing calculations associated with GD&T to determine the geometric requirements (d) applying the appropriate geometric control symbols, modifiers, and datum references to the engi- neering drawings and related documentation (e) applyingtheprinciples ofGD&Tto theoperations of manufacturing, qualitycontrol, and verification processes associated with engineering drawings and related documentation (f) applying the principles of GD&T to the establish- ment of functional gaging activities

2.2 Qualifications

2.2.1 Technologist GDTP. The requirement for certi- fication for a Technologist GDTP is to successfully pass the Technologist GDTP examination.

2.2.2 Senior GDTP. The requirements for certification for a Senior GDTP are as follows:

(a) 5 yr ofdocumented experience in the field ofGD&T intherecognizeduseofthesysteminbothapplicationand understanding.

(b) successfully passing the Senior GDTP examination. Anindividual is notrequired to be a certified Technologist GDTP to qualify for taking the Senior GDTP examination.

2.2.3 Equivalencies. NotethatASME Y14.5-2009 is not equivalent to ASME Y14.5M-1994. Successfully passing the ASME Y14.5-2009 examination does not confer certi- fication to ASME Y14.5M-1994. Successfully passing the ASME Y14.5M-1994 examination does not confer certifi- cation to ASME Y14.5-2009.ASME Y14.5.2 pdf download.ASME Y14.5.2-2017 pdf free download