ASME HST-3-2017 pdf free download.Performance Standard for Lever Hoists

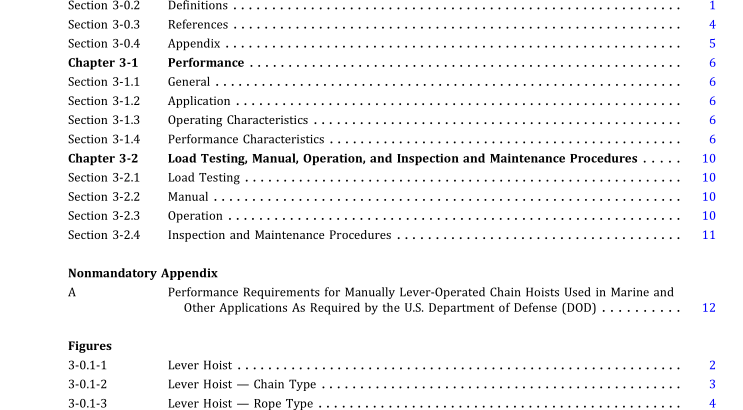

(a) This Standard establishes performance require- ments for chain, wire rope, and web strap lever hoists for lifting, pulling, and tensioning applications (see Figures 3-0.1-1, 3-0.1-2, 3-0.1-3, and 3-0.1-4).

(b) The specifications and information in this Standard apply to lever hoists of the following types:

(1) ratchet-and-pawl operation with

(-a) roller-type load chain lifting medium

(-b) welded-link-type load chain lifting medium

(-c) web-strap-type lifting medium

(-d) wire-rope-type lifting medium

(2) friction-brake operation with

(-a) roller-type load chain

(-b) welded-link-type load chain

(-c) web-strap-type lifting medium

(-d) wire-rope-type lifting medium

(c) Specially insulated lever hoists designed for hand- ling high-voltage lines are not covered by this Standard.

(d) This Standard is applicable to hoists manufactured after the date on which this Standard is issued. This Standard is not applicable to

(1) damaged or malfunctioning hoists

(2) hoists that have been misused or abused

(3) hoists that have been altered without authoriza- tion of the manufacturer or a qualified person

(4) hoists used for lifting or supporting people

(5) hoists used for the purpose of drawing both the load and hoist up or down the hoist’s own load chain(s), wire rope(s), or web strap(s)

(6) hoists used for marine and other applications as required by the Department of Defense (DOD). The requirements of this Standard shall be applied together with the requirements of ASME B30.21. Refer to ASME B30.21 for requirements pertaining to marking, construction, installation, inspection, testing, maintenance, and operation.

SECTION 3-0.2 DEFINITIONS abnormaloperating conditions: environmental conditions thatareunfavorable, harmful, ordetrimentalto the opera- tion of a hoist, such as excessively high or low ambient temperature, exposure to weather, corrosive fumes, dust-laden or moisture-laden atmospheres, and hazardous locations. brake: a device for retarding and stopping motion of the load (see load-controlling mechanism). hazardous (classified) locations: locations where fire or explosion hazards may exist. Locations are classified according to the properties of the flammable vapors, liquids, gases, or combustible dust or fibers that may bepresent,andthelikelihoodthataflammableorcombus- tible concentration or quantity is present.

Refer to ANSI/ NFPA 70. headroom (closedheight):thedistancebetweenthesaddle of the suspension hook and the saddle of the load hook when the load hook is in its fully retracted position (see Figure 3-0.1-1).

idler sprocket: a freely rotating device that changes the direction of the load chain, rope, or web strap. lever hoist: a manually lever-operated device used to lift, lower, or pull a load and to apply or release tension. lever pull: the average force, lbf (kN), exerted by the operator at the end of the operating lever (handle) to lift or pull rated load. lift: the maximum distance through which the load hook can travel (see Figure 3-0.1-1).

lifting devices: devices that are not normally reeved onto the hoist rope, web strap, or chain, such as supplemental devices used for handling or attaching to the load.

The weight of these devices is to be considered part of the load to be lifted. lifting medium: the chain, wire rope, or web strap used by the lever hoist to apply a force or support the load. load: the total superimposed force on the hoist load block or load hook. load block: the assembly ofhook or shackle, swivel, bearings, sheaves, sprockets, pins, andframesuspendedbythe load chain, rope, or web strap.

This shall include any appurtenances reeved into the load chain, rope, or web strap. load chain: the load-bearing chain in the hoist. roller chain: a series of alternately assembled roller links andpinlinks inwhichpins articulateinsidethebushings, and rollers are free to turn on the bushings. Pins and bushings are press-fit in their respective link plates.

welded-linkchain:achainconsistingofinterwovenlinks formed and welded.

NOTE: Load-chain properties do not conform to those shown in ASME B30.9.ASME HST-3 pdf download.ASME HST-3-2017 pdf free download