ASME B73.3-2015 pdf free download.Specification for Sealless Horizontal End Suction Centrifugal Pumps for Chemical Process

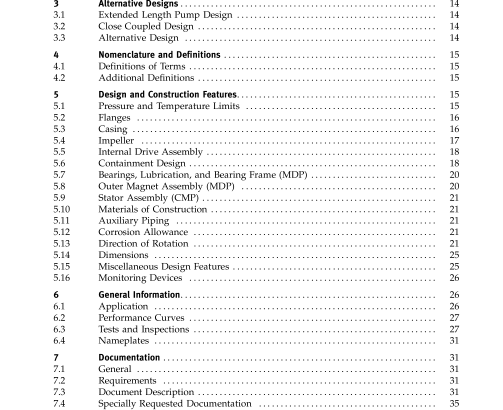

3 ALTERNATIVE DESIGNS

3.1 Extended Length

Pump Design An extended length pump design is an option for enhanced mechanical performance. Dimensions for an extended length pump design are included in this Standard. The extended length alternative shall conform to the design features of this specification including those providing interchangeability with respect to mounting dimensions at the casing, size, and location of the suction and discharge nozzles (see column heads with e suffix in Tables 1-1 and 1-1M through 3-2 and 3-2M for dimensional limits).

3.2 Close Coupled Design

Close coupled magnetic drive pumps have been allowed as an alternative design. The close coupled arrangement shall conform to the design features of this Standard including those providing interchangeability with respect to mounting dimensions at the casing, size, and location of the suction and discharge nozzles except there is no requirement for a separate pump bearing frame. Dimensions for close coupled pump baseplates are included in this Standard.

3.3 Alternative Design Otheralternative designswillbe considered,provided they meet the intent of this Standard and cover construction characteristics which are equivalent to and otherwise in accordance with these specifications. All deviations from these specifications shall be described in detail.

4 NOMENCLATURE AND DEFINITIONS

4.1 Definitions of Terms All nomenclature and definitions of pump compo- nents shall be in accordance with ANSI/HI 5.1 through ANSI/HI 5.6. canned motor pump (CMP): a type ofsealless pump where the impeller is mounted on the end of the shaft that is overhung from its motor bearing supports. The impeller is mounted directly on the rotor assembly, making one rotor assembly.

The bearings are supported by housings ateachend ofthe rotorassembly. The motor components are protected from the process liquid by corrosion resis- tant, nonmagnetic liners (shells). During operation, the motor section and bearings are either cooled and lubri- cated by the process liquid or a flush introduced from an external source. close coupled magnetic drive pump: a sealless magnetic drive pump as defined below except the outer magnet ring is mounted on the driver shaft. magnetic drive pump (MDP): a type of sealless pump where the impeller is mounted on a rotor assembly that contains the inner magnet ring of a magnetic drive.

The process fluid is retained by a corrosion resistant containment shell that separates the inner magnet ring and the outer magnet ring.

The outer magnet ring is mounted on the shaft of a frame that is coupled to a motor or power device. plastic lined sealless pump: a type of sealless magnetic drive pump which consists of a metal outer casing covered internally by a plastic lining for chemical resistance. The metal outer casing gives structural rigidity for pressure containment and externally applied nozzle loads. The containment shell may consist of a reinforced outer shell with a plastic insert for chemical resistance, an engineered ceramic or other nonmetallic construction. All nonpressure-containing wetted parts are either cov- ered by a plastic lining or may be made of an engineered ceramic. separatelycoupled magnetic drive pump: a sealless magnetic drive pump as defined above where the outer magnet ring is mounted on the shaft of a frame that is separately coupled to a motor or power device and mounted on a common baseplate.

4.2 Additional Definitions auxiliary piping: includes all piping connected to the pump excluding the main piping connected at the pump suction and discharge flanges. Auxiliary piping includes piping, tubing, and all attached components such as valves, instrumentation, and coolers.

5 DESIGN AND CONSTRUCTION FEATURES

5.1 Pressure and Temperature Limits

5.1.1 Pressure Limits. Pressure limitations shall be stated by the pump manufacturer. See para.

5.11 for auxiliary piping. 5.1.1.1 The design pressure of the casing, casing cover, containment shell, and secondary containment, if applicable, shall be at least as great as the pressure– temperature rating of ASME B16.5 Class 150 flanges or ASME B16.42 Class 150 flanges for the material used.ASME B73.3 pdf download.ASME B73.3-2015 pdf free download