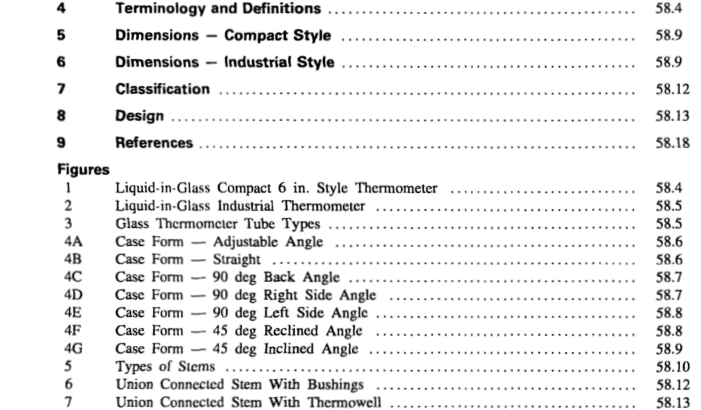

ASME B40.200-2001 pdf free download.LIUUIU-IN-tiLASS A — THERMOMETERS

his Standard is confined to analog, liquid-in-glass Industrial type thermometers for Industrial Applications that sense process temperature by means of the expan- sion of the liquid within the glass thermometer bulb. The liquid fill, based on the temperature to be measured, may be mercury or organic liquid. This Standard does not include laboratory type ASTM thermometers (Speci- fication Designation: ASTM E 1-86). NOTE: Themowell Standard ASME B40.9 does not include dimen- sional infomation or drawings for the internally tapered thermowell described in this Standard. This internally tapered themowell has been in continuous use since 1927.

The dimensional information listed is to be considered critical to insure interchangeability within the industry, for both new and existing thermometers.

2 HISTORY Since 1900 the introduction of the liquid-in-glass thermometer for pipe line, tankage, and other tempera- ture measuring applications became a reality. In such equipment, if the fitting attaching the thermometer to the equipment is not dimensionally standardized, extreme difficulty in replacing a thermometer is encountered. Over the years manufacturers have standardized the product. To accommodate the interchangeability, this endeavor has been helped by the introduction of Mili- tary, Federal, and Trade Association Standards. Dimen sional and other information from the following Liquid- in-Glass Industrial Thermometer specifications have been incorporated into this publication.

(a) F.S.B. No. 472, March 5, 1927 United States Government Master Specification for Thermometers, Industrial. “This specification was officially promul- gated by the Federal Specifications Board on March 5, 1927, for the use of the Departments and Independent Establishments of the Government in the purchase of industrial thermometers.” (From the title page of the specification.)

(b) GG-T-321, March 31, 1931, superceding U.S.G.M.S. 472a October i 928; Federal Specification, Industrial Thermometers

(c) 18T14(INT), November 1941, Thermometers, Mercurial, Navy Type, 6 in. case. Bureau of Ships

(d) 18?rj, July 1, 1944, superceding 18’L’j December 1937, Navy Department Specification; Thermometers, Industrial

(e) MIL-T-656, April 1953, Thermometer, Self Indi- cating, 6 in. case c

f) MIL-T-19474, Apnl 1956, Military Specification; Thermometer, Self Indicating, Liquid-in-Glass 6 in.

(g) MIL-T-19475, Apnl 1956, Military Specification; Thermometer, Self Indicating, Liquid-in-Glass, 7 in. and 9 in. case

(h) RC7-1, 1962 SAMA (Scientific Apparatus Mak- ers Association) Standard: Liquid-in-Glass Industrial Thermometers

(i) GG-T-32 Id, July 1977, Federal Specification, superceding GG-T-321c, dated 1962, Thermometers, Self Indicating, Liquid-in-Glass for Machinery and Pip- ing Systems NOTE: ALL OF THE ABOVE STANDARDS HAVE BEEN CANCELLED. THIS STANDARD RETAINS THE CRITICAL DIMENSIONS AND TERMINOLOGY OF THE CANCELLED STANDARDS. ASME has been granted authorization by SAMA to assume responsibility for the cancelled RC7- 1 Standard, and replace it with this B40.8 Standard

. 3 STYLE

3.1 Industrial size of 7 in., 9 in., or 12 in. See Fig. 4B. The thermometers described have a nominal case

3.2 Compact 6 in. The thermometers described are of a different design and are not interchangeable with Industrial Style of para. 3.1. The primary use for 6 in. nominal case size thermometer is for small diameter pipe lines, wherein shorter immersion length of thermowells is required, or mounting space for the thermometer is restricted. See Fig. i, sketches (a) and (b).

4 TERMINOLOGY AND DEFINITIONS

4.1 Thermometer Tube and Scale scale, thermometer: a thermometer scale is printed or engraved on metal, with the temperature range in readable lines and readable numerals. The scale is secured within the case with the test points on the thermometer tube aligned with the corresponding scale graduation. The height of the liquid column within the glass thermometer tube is then visually translated into temperature. Thermometer scales are graduated in de- grees Fahrenheit (OF), degrees Celsius (“C), or degrees Fahrenheit and Celsius (“FIOC). Formulas and abbrevia- tions for conversion of these temperature units are:

tube, thermometer: a thermometer tube manufactured of special thermometer glass capillary stem tube fused to a thermometer glass bulb and glass scale capillary tube, is a temperature-measuring component containing a liquid fill in which the liquid column is observed as an indication of temperature. For the adjustable type thermometer tube, a capillary of metal alloy is fused between the stem tube and the scale tube. The scale tube may be a magnifying lens for better visibility of the liquid column. See Fig. 3.ASME B40.200 pdf download.ASME B40.200-2001 pdf free download