ASME B36.10M-2018 pdf free download.Welded and Seamless Wrought Steel Pipe

This Standardcovers thestandardizationofdimensions ofwelded and seamless wroughtsteel pipe forhigh orlow temperatures and pressures. The word pipe is used, as distinguished from tube, to apply to tubular products of dimensions commonly used for pipeline and piping systems.

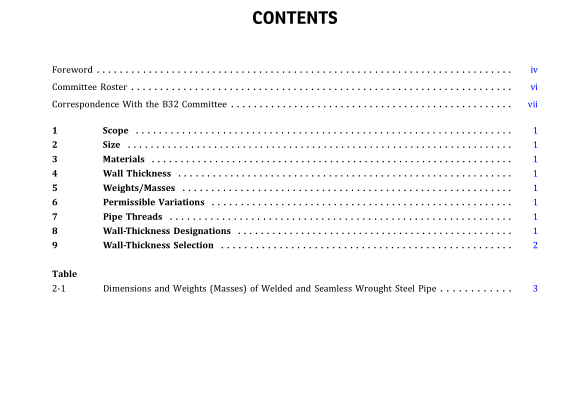

2 SIZE The size of all pipe in Table 2-1 is identified by the dimensionless designator nominal pipe size (NPS) [diamètre nominal (DN)]. Pipe NPS 12 (DN 300) and smaller have outside diameters numerically larger than their corresponding sizes. In contrast, the outside diameters of tubes are numerically identical to the size number for all sizes. The manufacture ofpipe NPS 1 ∕ 8 (DN 6) to NPS 12 (DN 300), inclusive, is based on a standardized outside diameter (O.D.). This O.D. was originally selected so thatpipe with a standard O.D. and having a wall thickness that was typical of the period would have an inside diameter (I.D.) approximately equal to the nominal size. Although there is no such relation between the existing standard thickness — O.D. and nominal size — these nominal sizes and standard O.D.s continue in use as “standard.” The manufacture of pipe NPS 14 (DN 350) and larger proceeds on the basis of an O.D. corresponding to the nominal size.

3 MATERIALS The dimensional standards for pipe described here are for products covered in ASTM specifications.

4 WALL THICKNESS The nominal wall thicknesses are given in Table 2-1.

5 WEIGHTS/MASSES The nominal weights (masses) of steel pipe are calcu- lated values and are tabulated in Table 2-1. The nominal plain end weight, in pounds per foot, is calculated using the following formula: = W D t t 10.69( ) pe where D = outside diameter to the nearest 0.001 in. (the symbol D is to be used for O.D. only in mathe- matical equations or formulas) t = specified wall thickness, rounded to the nearest 0.001 in. W pe = nominal plain end weight, rounded to the nearest 0.01 lb/ft The nominal plain end mass, in kilograms per meter, is calculated using the following formula: = M D t t 0.0246615( ) pe where D = outside diameter to the nearest 0.1 mm for outside diameters that are 16 in. (406.4 mm) and smaller and to the nearest 1.0 mm for outside diameters larger than 16 in. (406.4 mm) (the symbol D is to be used for O.D. only in mathematical equations or formulas) M pe = nominal plain end mass, rounded to the nearest 0.01 kg/m t = specified wall thickness, rounded to the nearest 0.01 mm

6 PERMISSIBLE VARIATIONS

Variations in dimensions differ depending upon the method of manufacture employed in making the pipe to the various specifications available. Permissible varia- tions for dimensions are indicated in each specification.

7 PIPE THREADS Unlessotherwisespecified,thethreadsofthreadedpipe shall conform to ASME B1.20.1, Pipe Threads, General Purpose (Inch). Schedules 5 and 10 wall thicknesses do not permit threading in accordance with ASME B1.20.1.

8 WALL-THICKNESS DESIGNATIONS The wall-thickness designations Standard, Extra- Strong, and Double Extra-Strong have been commercially used designations for many years. As explained in the Foreword, the Schedule Numbers were subsequently added as a convenient designation for use in ordering pipe. Standard and Schedule 40 are identical for up to NPS 10 (DN 250), inclusive. All larger sizes of Standard have 3 ∕ 8 in. (9.53 mm) wall thicknesses. Extra-Strong and Schedule 80 are identical for up to NPS 8 (DN 200), inclusive. All larger sizes of Extra-Strong have 1 ∕ 2 in. (12.70 mm) wall thicknesses. Pipe of sizes and wall thicknesses other than those of Standard, Extra-Strong, and Double Extra-Strong, and Schedule Number, were adopted from API Specification 5L, Line Pipe. It was not considered practical to establish Schedule Numbers or new designations for them.

9 WALL-THICKNESS SELECTION When the selection ofwall thickness depends primarily upon capacity to resist internal pressure under given conditions, the designer shall compute the exact value of wall thickness suitable for conditions for which the pipe is required, as prescribed in detail in the ASME Boiler and Pressure Vessel Code, ASME B31 Code for Pressure Piping, or other similar codes, whichever governs the construction. A thickness shall be selected from Table 2-1 to suit the value computed to fulfill the conditions for which the pipe is desired.ASME B36.10M pdf download.ASME B36.10M-2018 pdf free download