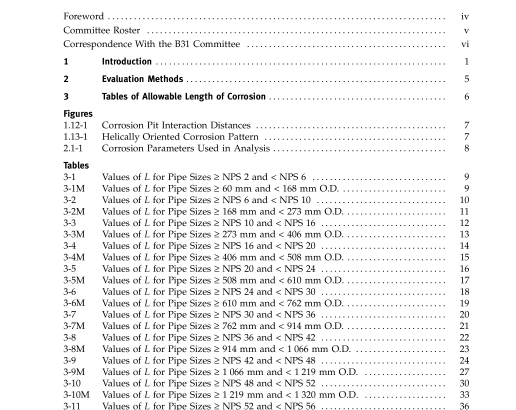

ASME B31G-2009 pdf free download.Manual for Determining the Remaining Strength of Corroded Pipelines

1.10 Software

The use of commercial or proprietary computer soft- ware packages, as well as purpose-written programs or spreadsheets, can greatly facilitate Level 1 evaluations, and is practically a necessity for conducting thorough Level 2 and Level 3 evaluations. It is the user’s responsi- bility to verify the accuracy and reliability ofall software and spreadsheets, and to train personnel in their correct usage. Validation of software should include documented evidence that correct results are obtained over the full range of parameters that could reasonably be expected to occur when making evaluations.

The following docu- ment summarizes the results of burst tests and service failures of line pipe affected by corrosion or artificial metal loss, and which have previously been used for the purpose of validating the evaluation methods presented herein: Kiefner, J. F., Vieth, P. H., and Roytman, I., “Continued Validation of RSTRENG,” PRCI Catalog No. L51749, Contract PR 218-9304, Dec. 20, 1996. Validation may be demonstrated by comparison of calculated results againstpublished benchmarktestdata such as that found in the above reference, or against results produced by another recognized evaluation method that have been calculated in accordance with this Standard. Validation ofthird-party software should also demon- strate that adequate checks or warnings are produced when parameters fall outside ranges that will ensure correct results.

1.11 Accuracy

Consideration should be given to the accuracy of recorded flaw sizes, particularly where indirect methods are used to locate and size the flaws. Methods account- ing for uncertainty in indirectly sized flaws include increasing the flaw dimension in order to account for detection tool error, or statistical analysis ofthe probable flaw sizes or risk of failure. Metal-loss corrosion anomalies indicated by inline inspection may be evaluated by a Level 1 or Level 2 evaluation method. The user is cautioned against over- stating the precision of evaluations applied with flaw dimensions indicated by inline inspection without ade- quate calibration or verification of actual flaw sizes by investigations carried out in the field.

1.12 Flaw Interaction The methods described hereinare suitable for evaluat- ing isolated areas of metal loss. Corrosion may occur such that multiple areas of metal loss are closely spaced longitudinally or transversely. If spaced sufficiently closely, the metal loss areas may interact so as to result in failure at a lower pressure than would be expected based on ananalysis ofthe separate flaws. The following guideline is suggested with reference to Fig.

1.12-1, based on limited testing and analysis:

(a) Flaws are considered interacting ifthey are spaced longitudinally or circumferentially from each other within a distance of 3 times the wall thickness (3t). Inter- acting flaws should be evaluated as a single flaw com- bined from all interacting flaws.

(b) Flaws are considered noninteracting ifspaced out- side of the above dimensions. Noninteracting flaws should be evaluated as separate flaws. Care should be exercised when grouping or clustering anomalies indicated by inline inspection for purposes of evaluating interaction during the prioritization process. Consideration should be given to minimum thresholds of metal loss for reliable detection and sizing, minimum thresholds for reporting, and the expected mode of coat- ing failure (e.g., localized failure versus disbondment over large areas). Methods employed for clustering of inline inspection anomalies should be validated by field verification of actual flaw dimensions and spacing.

1.13 Flaw Orientation Corrosion caused by disbondment of continuous wrapped coatings may exhibit a helical pattern. If the helical patternlies atanangle less than45 deg to the pipe axis, the overall length of the corroded area indicated as L 1 in Fig.

1.13-1 shall be considered in the evaluation. If the helical pattern lies at an angle of 45 deg or greater to the pipe axis, it is sufficient to consider the most severe longitudinal section through the corroded area having a length L 2 in Fig. ASME B31G pdf download.ASME B31G-2009 pdf free download