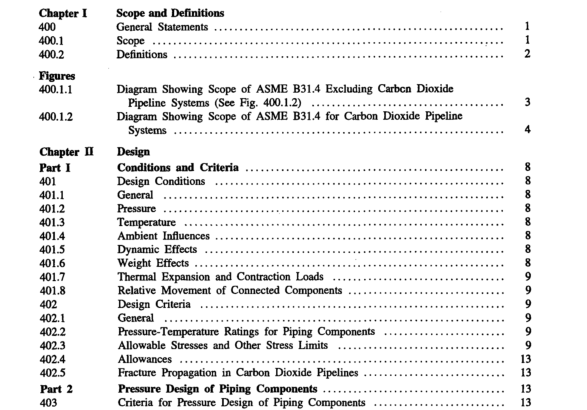

ASME B31.4-2002 pdf free download.PIPEUNE TRANSPORTATIOM SYSTEMS FOR LIIIUID HYDROCARBONS AND OTHER 1IQUlDS

401.6.2 Dead Loads. Dead loads include the weightof the pipe,components,coating,backfill,and unsup-ported attachments to the piping.

401.7 Thermal Expansion and Contraction LoadsProvisions shall be made for the effects of thermalexpansion and contraction in all piping systems.

401.8 Relative Movement of Connected ComponentsThe effect of relative movement of connected compo-nents shall be taken into account in design of pipingand pipe supporting elements.

402 DESIGN CRrTERIA402.1 General

Paragraph 402pertains to ratings,stress criteria,design allowances,and minimum design values,andformulates the permissible variations to these factorsused in the design of piping systems within the scopeof this Code.

The design requirements of this Code are adequatefor public safety under conditions usually encounteredin piping systems within the scope of this Code,including lines within villages,towns,cities,and industrialareas. However,the design engineer shall provide reasonable protection to prevent damage to the pipelinefrom unusual external conditions which may be encountered in river crossings,inland coastal water areas,bridges, areas of heavy traffic, long self-supported spans,unstable ground,vibration,weight of special attachments, or forces resulting from abnormal thermal conditions. Some of the protective measures which the designengineer may provide are encasing with steel pipe oflarger diameter,adding concreteprotective coating,increasing the wall thickness,lowering the line to agreater depth,or indicating the presence of the linewith additional markers.

402.2 Pressure-Temperature Ratings for Piping

Components

402.2.1 Components Having Specific Ratings.Within the metal temperature limits of -20°F(-30°C)to 250°F (120°c), pressure ratings for components shall conform to those stated for 100°F (40°C) in material standards listed in Table 423.1. The nonmetallic trim, packing, seals, and gaskets shall be made of materials which are not injuriously affected by the fluid in the piping system and shall be capable of withstanding the pressures and temperatures to which they will be subjected in service. Low temperatures due to pressure reduction situations, such as blow downs and other events, shall be considered when designing carbon dioxide pipelines.

402.2.2 Ratings – Components Not Having Spe- cific Ratings. Piping components not having established pressure ratings may be qualified for use as specified in paras.

404.7 and 423.1(b). 402.2.3 Normal Operating Conditions. For normal operation the maximum steady state operating pressure shall not exceed the internal design pressure and pressure ratings for the components used. 402.2.4 Ratings – Allowance for Variations From Normal Operations. Surge pressures in a liquid pipeline are produced by a change in the velocity of the moving stream that results from shutting down of a pump station or pumping unit, closing of a valve, or blockage of the moving stream. Surge pressure attenuates (decreases in intensity) as it moves away from its point of origin. Surge calculations shall be made, and adequate con- trols and protective equipment shall be provided, so that the level of pressure rise due to surges and other variations from normal operations shall not exceed the internal design pressure at any point in the piping system and equipment by more than 10%.

402.2.5 Ratings – Considerations for Different Pressure Conditions. When two lines that operate at different pressure conditions are connected, the valve segregating the two lines shall be rated for the more severe service condition. When a line is connected to a piece of equipment which operates at a higher pressure condition than that of the line, the valve segregating the line from the equipment shall be rated for at least the operating condition of the equipment. The piping between the more severe conditions and the valve shall be designed to withstand the operating conditions of the equipment or piping to which it is connected.ASME B31.4 pdf download.ASME B31.4-2002 pdf free download