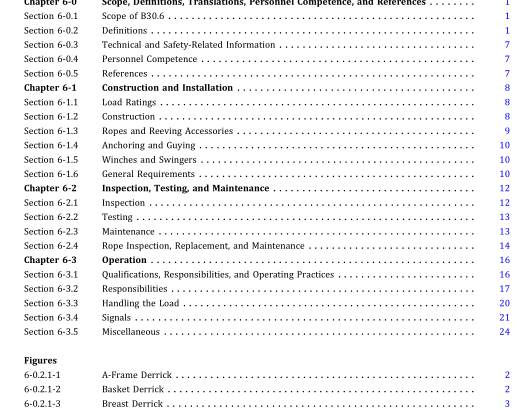

ASME B30.6-2020 pdf free download.Derricks Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings

6-1.2.4 ð20Þ Gin Pole Derricks

(a) Guylines shallbesizedandspacedsoasto makethe gin pole stable in both boomed and vertical positions.

(b) The base of the gin pole shall

(1) permit movement of the pole

(2) provide means to anchor the pole against hori- zontal forces 6-1.2.5 Chicago Boom Derricks Thefittings forsteppingthe boomandforattachmentof the topping lift shall be arranged to

(a) permit the derrick to swing at all permitted oper- ating radii and mounting heights between fittings

(b) accommodateattachmentto theuprightmemberof the host structure

(c) withstand the forces applied during normal opera- tion with rated loads at permitted operating configura- tions (d) prevent the boom or topping lift from lifting out under tensile forces

SECTION 6-1.3: ROPES AND REEVING ACCESSORIES 6-1.3.1 General Wherever exposed to temperatures in excess of 180°F (82°C), rope having an independent wire rope core, wire strand core, or other temperature damage-resistant core shall be used.

6-1.3.2 Guy Ropes

(a) Guyropes shall be ofa size, grade, and construction to withstand the maximum load imposed.

(b) The minimum breaking force ofeach rope shall not be less than 3 times the static load applied to the rope.

(c) Guy attachments such as turnbuckles shall have provision to prevent loosening during usage.

6-1.3.3 Boom Hoist Ropes

(a) Boom hoist ropes shall be of a size, grade, and construction to withstand the maximum load imposed.

(b) The live rope-reevingsystem in a boom suspension shall withstand the maximum load imposed and be of a length to permit lowering the boom point to horizontal position with at least two full wraps of rope remaining on the drum.

(c) The minimum breaking force of the most heavily loaded rope in a system shall not be less than 3 1 ∕ 2 times the load applied to that rope.

(d) Rotation resistantropes shall notbe used for boom hoist reeving.

6-1.3.4 Load Hoist Ropes

(a) Load hoist ropes shall be of a size, grade, and construction to withstand the maximum load imposed.

(b) Ropes in the load-hoisting systems shall be of a length for the entire range of movement specified for the application with at least two full wraps of rope remaining on the drum.

(c) The minimum breaking force of the most heavily loaded rope in a system shall not be less than 3 1 ∕ 2 times the load applied to that rope, except as specified in (d).

(d) Rotation-resistant ropes shall have a design factor of 5 or greater. [The design factor of 5 or greater for rotation-resistant ropes may be modified by the derrick user by complying with the provisions of para. 6-3.3.1(c)].

(e) Rotation-resistant ropes shall be given special care ininstallationastheyaremoresusceptibletodamagethan other types of rope. NOTE: The rope design factors, as given in paras.

6-1.3.2 through 6-1.3.4, shall be determined on the basis ofrope loads resulting from rated loads, specified reeving, and published minimum breaking force ofnew rope. Consideration shall be given to fric- tional losses where appropriate. Ropes ofmaterial other than steel may be used only in accor- dance with the manufacturer’s, or a qualified person’s, recommendation.

6-1.3.5 Reeving Accessories

(a) Poured, swaged, compressed, or wedge socket fittings shall be applied as recommended by the rope, derrick, or fitting manufacturer. Any new poured socket or swaged socket assembly used as a boom pendant shall be proof tested to the derrick or fitting manufacturer’s recommendation but in no case greater than 50% of the minimum breaking force of the compo- nent wire ropes, structural strands, or fittings.

(b) Rope end shall be anchored to the drum.

(c) Eyes shall be made in a recommended manner, and rope thimbles should be used in the eye.

(d) Rope clips attached with U-bolts shall have the U-bolt on the dead or short end of the rope. Spacing and number of all types of clips shall be in accordance with the clip manufacturer’s recommendations. Nuts on clip bolts shall be tightened evenly to the manufac- turer’s recommended torque. After the initial load is applied to newly installed rope and the rope is under tension, the nuts on the clip bolts should be tightened again to the required torque in order to compensate for any decrease in rope diameter caused by the load.

(e) Where a half-wedge socket is used, it shall be of a positive-locking type.ASME B30.6 pdf download.ASME B30.6-2020 pdf free download