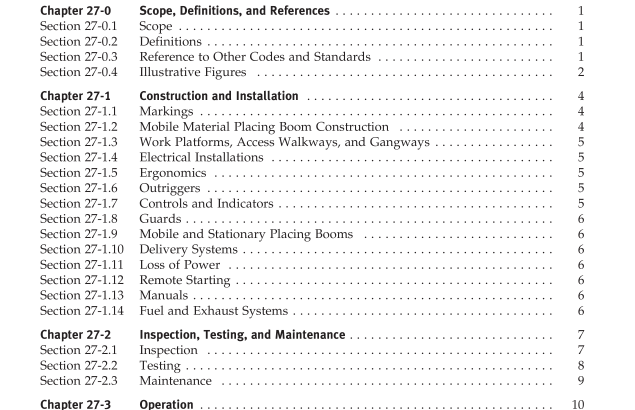

ASME B30.27-2005 pdf free download.Material Placement Systems Safety Standard for Cableways, Cranes, Derricks Hoists, Hooks, Jacks, and Slings

SECTION 27-0.1: SCOPE Volume B30.27 includes provisions that apply to the construction, installation, operation, inspection, and main- tenance of mobile material placing booms, mobile telescoping boom conveyors, separate placing booms, and material placement accessories (see Figs. 1 through 3). This Volume does not apply to the pumping elements of a concrete pump, conveyors, mortar convey- ing or spraying machines, or dry mix shotcreting machines. The concrete pump portion of these machines is cov- ered by CPMA 27-2000. The conveyor section of these machines is covered by ASME B20.1.

SECTION 27-0.2: DEFINITIONS concrete delivery hose: a flexible delivery hose having a coupling on each end. control panel: controls mounted on the material placement system. delivery systems: delivery lines, pipes, hoses, attachment components, and transfer valves, through which mate- rial is transported (see Fig. 4).

designated person: a person selected or assigned by the employer or the employer’s representative as being competent to perform specific duties.

end hose: a flexible concrete delivery hose that only has one coupling. manual valve override: a mechanical valve actuator used to operate an electrically controlled valve in emergency or breakdown situations.

manual valves: a valve whose manual actuator is the only means of valve actuation.

maximum support force: the maximum force exerted on the supporting surface at any one outrigger.

normal operating conditions: conditions during which a material placement system is performing functions within the scope of the original design. Under these conditions, no one other than the operator is on the material placement system.

outrigger: extendable or fixed members attached to the mounting base, which rest on supports at the outer ends used to support the machine.

placing booms: manual or power driven, slewable work- ing devices, consisting of one or more extendable or foldable parts supporting the material delivery system, and directing the discharge into the desired location. priority switching: transferring control of one or more functions from a control location to a different control location. qualified person: a person who, by possession of a recognized degree in an applicable field, or certificate of pro- fessional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated the ability to solve or resolve problems relating to the subject matter and work. rated load: maximum allowable working load designated by the manufacturer.

remote control: a portable control device connected to the machine by a wire cable or linked by radio or other means. safety device: a means placed in use for the specific purpose of preventing an unsafe condition.

sheave: a grooved wheel or pulley used with a rope to change the direction and point of application of a pulling force. shortrigging: one or more outriggers not fully extended on the side away from the boom operational area. signal person: see spotter.

specific type (of material placement system): a model, style, or size classification of material placement system (e.g., three section boom, four section boom, 50 meter class, conveyor).

spotter: a signal person/spotter is a person positioned at a vantage point where both the point of discharge and the operator of the material placement system can be seen and relays information to the operator.ASME B30.27 pdf download.ASME B30.27-2005 pdf free download