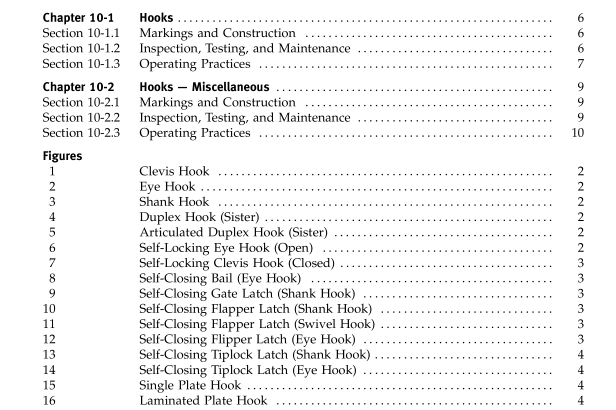

ASME B30.10-2005 pdf free download.Hooks Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings

10-1.2.2 Testing

(a) When proof tests are used to verify manufacturing process, material, or configuration, the hooks shall be able to withstand the proof load application without permanent deformation when the load is applied for a minimum of 15 sec. This condition shall be considered to have been satisfied if the permanent increase in the throat opening does not exceed 1% or 0.02 in. (0.5 mm), whichever is greater. For such tests, Table 1 states the proof loads that shall be applied to a hook having a rated load capacity.

(b) For a duplex (sister) hook having a pin hole, the proof load for the pin hole shall be in accordance with Table 1. The proof load on the hook shall be shared equally between the two prongs of a sister hook, unless designed for unbalanced loading.

(c) Performance testing of hooks shall not be required except where necessary to conform to the requirements for the equipment of which they are a part.

10-1.2.3 Maintenance (a) Any conditions disclosed by the inspections performed in accordance with the requirements of para.

10- 1.2.1.2 or 10-1.2.1.3 shall be corrected by repair or replacement before continuing to use the hook. Hooks shall be removed from service unless a quali- fied person approves their continued use and initiates corrective action. (b) Hooks having damage or wear described as fol- lows shall be repaired or replaced:

(1) cracks, nicks, and gouges [see para. 10-1.2.3(e) below]

(2) wear exceeding 10% (or as recommended by the manufacturer) of the original sectional dimension

(3) any visibly apparent bend or twist from the plane of the unbent hook

(4) any distortion causing an increase in throat opening of 5%, not to exceed 1 ⁄ 4 in. (or as recommended by the manufacturer)

(5) inability of self-locking hooks to lock (c) A hook latch, when required, that is inoperative shall be repaired or replaced.

(d) A hook with a latch that does not close the throat opening shall be removed from service or moused until the latch is replaced or repaired.

(e) Repair ofcracks, nicks, and gouges shall be carried out by a designated person by grinding longitudinally, following the contour of the hook, provided no dimen- sion is reduced more than 10% (or as recommended by the manufacturer) of its original value. (f) All other repairs shall be performed by the manu- facturer or a qualified person.

(g) Replacement parts, such as load pins for clevis hooks, shall be at least equal to the original manufacturer’s specifications.

SECTION 10-1.3: OPERATING PRACTICES Personnel using hooks shall be aware ofthe following:

(a) It shall be determined that the weight of the load to be lifted does not exceed the lesser of the load rating of the hook or the load rating of the equipment of which the hook is a part.

(b) Shock loading should be avoided.

c) Load shall be centered in the base (bowl/saddle) of the hook to prevent point loading of the hook.

(d) Hooks shall not be used in such a manner as to place a side load or back load on the hook.

(e) When using a device to close the throat opening of the hook, care shall be taken that the load is not carried by the closing device.

(f) Hands, fingers, and body shall be kept from between hook and load.

(g) Duplex (sister) hooks shall be loaded equally on both sides unless the hook is specifically designed for single loading. When usingan articulated duplex (sister) hook (see Fig. 5), care should be taken because articula- tion of the hook may cause instability in the slung load.ASME B30.10 pdf download.ASME B30.10-2005 pdf free download