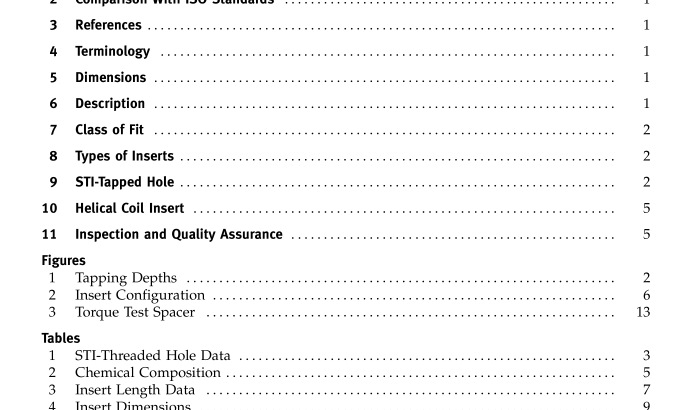

ASME B18.29.2M-2005 pdf free download.Helical Coil Screw Thread Inserts: Free Running and Screw Locking (Metric Series)

4 TERMINOLOGY Fordefinitionsofterms relatingto fasteners orcompo- nent features thereof used in this Standard, refer to ASME B18.12.

5 DIMENSIONS

(a) Unless otherwise stated, all dimensions in this Standard are in millimeters and apply before any coat- ing. When plating or coating is specified, the finished product dimensions shall be as agreed upon by the sup- plier and purchaser.

(b) Symbols specifying geometric characteristics are in accordance with ASME Y14.5M. 6 DESCRIPTION Helical coil inserts are screw thread bushings coiled from wire of diamond-shape crosssection. Inserts are screwed into STI-tapped holes to form nominal size internal threads. Inserts are installed by torquing through a diametral tang. This tang is notched for removalafterinstallation. Inthe free state, theyarelarger in diameter than the tapped hole into which they are installed. In the assembly operation, the torque applied to the tang reduces the diameter of the leading coil and permits it to enter the tapped thread. The remaining coils are reduced indiameter as they, inturn, are screwed into the tapped hole. When the torque or rotation is stopped, the coils expand with a spring-like action anchoring the insert in place against the tapped hole.

7 CLASS OF FIT

7.1 Tolerance Classes 4H5H and 5H Since helical coil inserts are flexible, the class of fit of the final assembly is a function of the size of the tapped hole. Helical coil STI taps are available for bothTolerance Class 4H5H– (or Class 4H6H–) and Class 5H–tapped holes. Tolerance Class 5H–tapped holes provide maxi- mum production tolerances but result in lower locking torques when screw-locking inserts are used. The higher and more consistent torques given in Table 5 are met by the screw-locking inserts when assembled and tested inTolerance Class 4H5H–(or Class 4H6H–) tapped holes in accordance with para. 9.

7.2 Compatibility Assembled helical coil inserts will mate properly with items that have M Profile external threads in accordance with ASME B1.13M. Also, due to the radius on the crest of the insert at the minor diameter, the assembled insert will mate with MJ Profile externally threaded parts with controlled radius root threads per ASME B1.21M.

8 TYPES OF INSERTS

8.1 Free-Running The free-running insert provides a smooth, hard, and free-running thread. 8.2 Screw-Locking The screwlocking insert provides a resilient locking thread produced by a series of chords on one or more of the insert coils.

9 STI-TAPPED HOLE The tapped hole into which the insert is installed shall be in accordance with ASME B1.13M, except that diame- ters are larger to accommodate the wire cross-section of the insert (see Fig. 1). Dimensions ofthe STI-tapped hole are shown in Table 1 and are calculated per General Note (c) to Table 1.

9.1 Screw Thread Designation

9.1.1 Designation for Tapped Hole. The drawing note for the STI-threaded hole per Table 1 to accept the helical coil insert shall be in accordance with the following example: EXAMPLE: M8 1.25-5H STI; 23.5 T per ASME B18.29.2M.

9.1.2 Designation for a Helical Coil Insert

(a) Helical coil inserts shall be designated by the following data, in the sequence shown:

(1) product name

(2) designation of the standard

(3) nominal diameter and thread pitch

(4) nominal length

(5) insert type (free-running or screw-locking)

9.1.3 Designation for STI-Threaded Hole Including Installed Helical Coil Insert. The drawing note for the STI-threaded hole per Table 1 having a helical coil insert installed shall be in accordance with this example. EXAMPLE: M8 ? 1.25 STI 23.5 deep; Helical Coil insert, ASME B18.29.2M, M8 1.25 12.0, free- running

9.2 Gages and Gaging Acceptance of the threaded hole is determined by gaging with STI GO, NOT GO (HI), and plain cylindrical gages designed and applied in accordance with System 21 of ASME B1.3M and with ASME B1.16M.ASME B18.29.2M pdf download.ASME B18.29.2M-2005 pdf free download