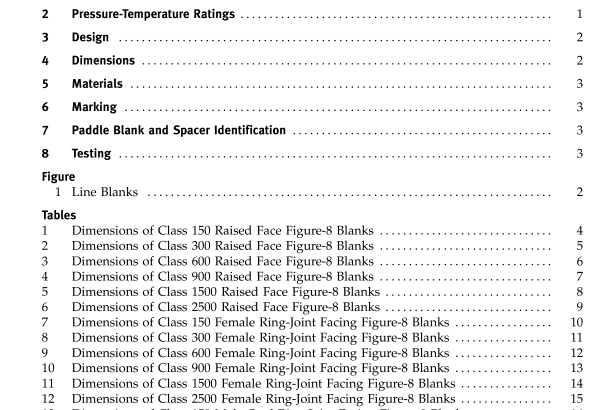

ASME B16.48-1997 pdf free download.Line Blanks

This Standard covers pressure-temperature ratings, materials, dimensions, tolerances, marking, and testing for operating line blanks in sizes NPS 1 ⁄ 2 through NPS 24 for installation between ASME B16.5 flanges in the 150, 300, 600, 900, 1500, and 2500 pressure classes.

1.2 Definitions

1.2.1 Figure-8 Blank. A figure-8 blank (also called a spectacle blank) is a pressure-retaining plate with one solid end and one open end connected with a web or tie bar (see Fig. 1).

1.2.2 Paddle Blank. A paddle blank is similar to the solid end of a figure-8 blank. It has a plain radial handle. It is generally used in conjunction with a paddle spacer in large sizes.

1.2.3 Paddle Spacer. A paddle spacer is similar to the open end of a figure-8 blank. It has a plain radial handle. It is generally used in conjunction with a paddle blank.

1.3 References Codes, standards, and specifications, containing pro- visions to the extent referenced herein, constitute requirements of this Standard. These reference docu- ments are listed in Nonmandatory Appendix B.

1.4 Quality Systems Nonmandatory requirements relating to the product manufacturer’s Quality System Program are described in Nonmandatory Appendix C.

1.5 Relevant Units This Standard states values in both Metric and U.S. Customary units. These systems of units are to be regarded separately as standard. Within the text, the U.S. Customary units are shown in parenthesis or sepa- rate tables. Refer to Nonmandatory Appendix A. The values stated in each system are not exact equivalents; therefore, it is required that each system of units be used independently of the other. Combining values from the two systems constitutes nonconformance with the Standard. Nonmandatory Appendix A provides dimensions in U.S. Customary units.

1.6 Convention For the purpose of determining conformance with this Standard, the convention for fixing significant digits where limits and maximum and minimum values are specified, shall be rounded as defined in ASTM Practice E 29. This requires that an observed or calcu- lated value shall be rounded off to the nearest unit in the last right-hand digit used for expressing the limit. Decimal values and tolerances do not imply a particular method of measurement.

1.7 Size NPS, followed by a dimensionless number, is the des- ignation for nominal blank size. NPS is related to the reference nominal diameter, DN, as defined in ISO 6708. The relationship is typically as follows:

NOTE: For NPS ≥ 4, the related DN is DN p 25 (NPS).

1.8 Service Conditions Criteria for selection of materials suitable for particu- lar fluid service are notwihtinthe scope ofthis Standard.

2 PRESSURE-TEMPERATURE RATINGS

2.1 Pressure Classes Line blanks covered by this Standard are for the fol- lowing pressure classes: 150, 300, 600, 900, 1500, and 2500 as listed in ASME B16.5.

2.2 Pressure-Temperature Ratings

2.2.1 Ratings. Ratings are the maximum allowable working gage pressure at the temperature shown in Tables 2 and F-2 of ASME B16.5 for the appropriate material and pressure class. For intermediate tempera- tures, linear interpolation between temperatures within a pressure class is permitted by ASME B16.5.

2.2.2 System Pressure Testing. Line blanks may be subjected to system tests at a pressure not to exceed 1.5 times the 38°C (100°F) rating rounded off to the next higher 1 bar (25 psi) increment. Testing at any higher pressure is the responsibility of the user, taking into account the requirements of the applicable code or regulation.

2.2.3 Mixed Material Joints. Should either the two flanges or the line blank in a flanged line blank assembly not have the same pressure-temperature rating, the rating of the assembled joint at any temperature shall be thelower oftheflange or line blankratingatthattemperature.

3 DESIGN

3.1 Handle The handle orweb (tie bar) maybe integral orattached to the line blank or spacer. The web and its attachment shall be capable of supporting the weight of the blank or spacer in all orientations without permanent defor- mation to the web.

3.2 Edge Preparation Finished surfaces shall be free of projections that would interfere with gasket seating. ASME B16.48 pdf download.ASME B16.48-1997 pdf free download