ASME B16.4-2021 pdf free download.Gray Iron Threaded Fittings Classes 125 and 250

4 SIZE

4.1 Nominal Pipe Size As applied in this Standard, the use of the phrase “nominal pipe size” or the designation NPS followed by a dimensionless number is for the purpose ofidentifying the end connection of fittings. The number is not neces- sarily the same as the fitting inside diameter.

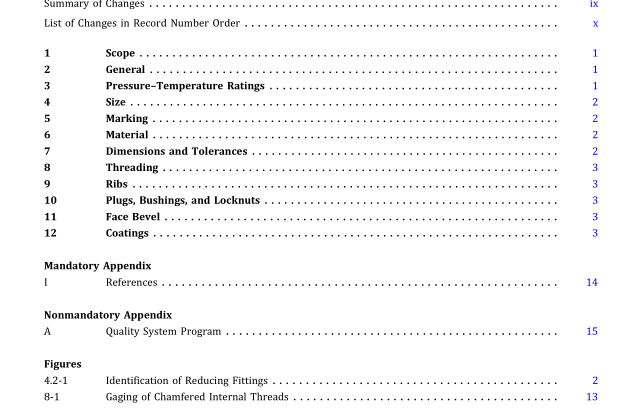

4.2 Reducing Fittings Forreducingtees and crosses, the size ofthe largestrun opening shall be given first, followed by the size of the opening at the opposite end of the run. Where the fitting is a tee, the size of the outlet is given last. Where the fitting is a cross, the largest side-outlet opening is the third dimension given, followed by the opposite opening. The straight-line sketches of Figure 4.2-1 illustrate how the reducing fittings are read.

5 MARKING (a) Each Class 125 fitting shall be marked for identification with the manufacturer’s name or trademark. (b) Each Class 250 fitting shall be marked for identification with (1) the manufacturer’s name or trademark (2) the numeral “250”

6 MATERIAL

Castings shall be produced to meetthe requirements of ASTM A126, Class A, B, or C. The manufacturer shall be prepared to certifythatthe producthas been so produced and that the chemical and physical properties thereof, as proved by test specimens, are equal to these require- ments. 7 DIMENSIONS AND TOLERANCES 7.1 General Center-to-end dimensions in millimeters are given for standard straight and reducing fittings in Tables 7.1-1 through 7.1-5. The sketches of fittings that accompany the tables are representative and for the purpose ofillustration.

7.2 Reducing Fittings

7.2.1 The dimensions of reduced fittings shown in Tables 7.1-2 and 7.1-3 are for use only when making patterns for the specific reducing fitting in question and do not apply when a larger size pattern is reduced (i.e., “bushed”) to make the reduction or reductions in thefitting. Reducingpipefittingpatterns shall bedesigned to produce wall thicknesses, detail, and dimensions as required for the sizes involved. 7.2.2 Thetransitionin wallth icknes sfrom oneendsize to another shall be in a manner that minimizes the addi- tion of stress caused by sudden changes in direction or wall thickness.

7.2.3 Proofofdesign shall be verified by a hydrostatic pressuretestmadeatambienttemperatureinwhichpres- sure is applied continuously for no less than 1 min and at no less than 5 times the pressure rating ofthe largestsize ofendconnectioninthereducingfitting. Testingis consid- ered successful only when no evidence of cracking, frac- turing, or leakage is exhibited after holdingfor atleastthe minimum time at or above the required pressure.

7.3 Tolerances The following tolerances shall be permitted: (a) Metal Thickness Tolerances. At no point in the cast- ings shallthemetalthickness belessthan90% ofthevalue given in Table 7.1-1, 7.1-4, or 7.1-5. (b) Center-to-End Tolerances. Permitted tolerances on the center-to-end dimensions ofthe fittings are shown in Table 7.3-1. Tolerances for end-to-end dimensions and lengths of couplings and reducers shall be twice those given. The largest opening in a reducing fitting governs the tolerances to be applied to all openings. These toler- ances do not apply to return bends and caps.

8 THREADING (a) All fittings shall be threaded according to ASME B1.20.1, and the variations in threading shall be limited to one turn large or one turn small from the gaging notch on the plug when using working gages. (b) The reference point for gaging internal fittings threads depends on the chamfer diameter. When the internal chamfer diameter exceeds the major diameter of the internal thread, the reference point is the last thread scratch on the chamfer cone. When the internal chamfer diameter does not exceed the major diameter of the internal thread, the reference point is the end of the fitting (see Figure 8-1). (c) For the purpose ofeasierentrance in makinga joint and for protection ofthe thread, all threads shall be coun- tersunka distance ofnotless than one-halfthe pitch ofthe threadatan angle ofapproximately45 degwith the axis of the thread. Countersinking shall be concentric with the threads. (d) The length ofthe threads specified in all tables shall be measured to include the countersink. (e) The maximum allowable variation in the alignment of threads of all openings of threaded fittings shall be 5.0 mm/m (0.06 in./ft) (0.5% slope). ASME B16.4 pdf download.ASME B16.4-2021 pdf free download