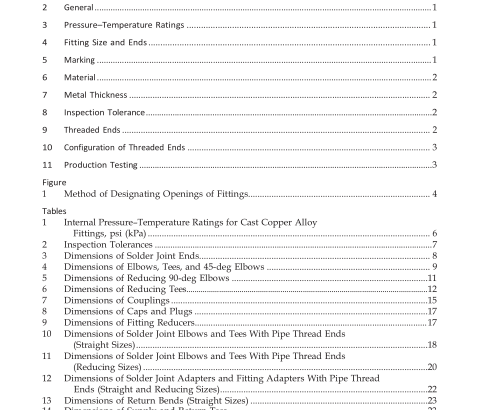

ASME B16.18-2012 pdf free download.Cast Copper Alloy Solder Joint Pressure Fittings

This Standard for cast copper alloy solder joint pres- sure fittings designed for use with copper water tube establishes requirements for (a) pressure–temperature ratings (b) abbreviations for end connections (c) sizes and method of designating openings of fittings (d) marking (e) material (f) dimensions and tolerances (g) tests 2 GENERAL

2.1 Relevant Units

This Standard states values in both SI (Metric) and U.S. Customary units. These systems of units are to be regarded separately as standard. Within the text, the SI units are shown in parentheses or in separate tables that appear in Mandatory Appendix I. The values stated in each system are not exact equivalents; therefore, it is required that each system of units be used indepen- dently of the other. Combining values from the two systems constitutes nonconformance with the Standard.

2.2 References

Standards and specifications adopted by reference in this Standard are shown in Mandatory Appendix II, which is part of this Standard. It is not considered practi- cal to identify the specific edition of each standard and specification in the individual references. Instead, the specific edition reference is identified in Mandatory Appendix II.

2.3 Quality System Requirements relating to the product manufacturer’s quality system programs are described in Nonmandatory Appendix C.

3 PRESSURE–TEMPERATURE RATINGS

3.1 Rating of Fitting and of Joint The internal pressure–temperature ratings of the fit- tings are shown in Table 1. The internal pressure–temperature rating for a solder joint fitting is dependent not only on fitting and tube strength, but also on the composition of the solder used for the joint and selection of valves and appurtenances. The internal pressure–temperature rating of the system shall be the lowest of the values shown in Table 1, the solder joint, and those of the tube, valves, or appurtenances. The maximum recommended pressure–temperature ratings for solder joints using the dimensions of Table 3 and Table I-3, made with typical commercial solders, are given in Nonmandatory Appendix A.

3.2 Bursting Strength Burst strength at 73°F ± 5°F (23°C ±2°C) shall not be less than four times the 100°F (38°C) internal working- pressure rating shown in Table 1. For reducing fittings, the applicable internal working pressure shall be that of the largest size of end connection.

4 FITTING SIZE AND ENDS The size of the fittings shown in Table 3 and Table A-1 corresponds to standard water tube size as shown in ASTM B88, Standard Specification for Seamless Copper Water Tube. The size of the threaded ends corresponds to nominal pipe size as shown in ANSI/ASME B1.20.1. Fittings are designated by the size of the openings in the sequence illustrated in Fig. 1. The following symbols are used to designate the type of fitting end: C p solder-joint fitting end made to receive copper tube diameter (female) F p internal ANSI standard taper pipe thread (female) NPT FTG p solder-joint fitting end made to copper tube diameter (male) M p external ANSI standard taper pipe thread (male) NPT 5 MARKING Each fitting shall be permanently marked with the manufacturer’s name or trademark and other applicable markings as required by MSS SP-25. Marking of fittings less than Standard Water Tube Size 1 ⁄ 2 , or on any fitting where it damages soldering surfaces is not required. Fittings manufactured from cast copper alloys con- taining silicon shall be permanently marked with the designation Si.ASME B16.18 pdf download.ASME B16.18-2012 pdf free download