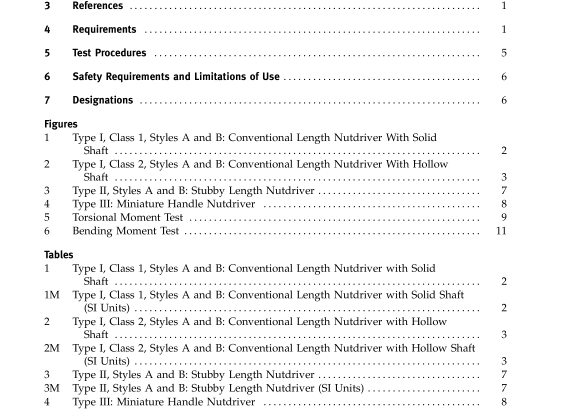

ASME B107-2004 pdf free download.Nutdrivers

4.8.2 Handle Shape and Finish. Handles shall be suit- ably shaped and finished to provide a comfortable grip. They shall be free from rough edges, sharp corners, or tool marks that affect the appearance and comfort of the tool. They shall meet the dimensional requirements specified in the applicable tables. 4

.8.3 Handle With Internal Drive. When specified, handles shall be provided with a 1 ⁄ 4 in. (6.3 mm) or 3 ⁄ 8 in. (10 mm) square internal drive opening. Square drive dimensions and tolerances shall be in accordance with ASME B107.4M. The drive shall be flush with the butt end of the handle. The drive shall be capable of meeting the same torsional load requirements as set forth for the socket end contained herein. A square external drive tang in accordance with ASME B107.4M shall be used for the test mandrel.

4.8.4 Cushion Grip. Style B nutdriver handles shall be furnished with cushion grips. The grip material shall be capable ofmeeting the handle solventtestas specified in para. 5.3. The length of the cushion grip shall be at least 60% of the handle length, and there shall be no detectable slippage between the handle and the cushion grip under normal usage. The original hardness shall be Shore A50 to A75 when tested in accordance with 5 ASTM D 2240 and the hardness after the solvent test shall not be greater than Shore A80. WARNING: Cushion grips are not intended to give any degree of protection against electric shock and shall not be used on or near live electrical circuits.

5 TEST PROCEDURES Many of the tests herein are inherently hazardous; adequate safeguards for personnel and property shall be employed in conducting these tests.

5.1 Torsional Moment Test Test shall be conducted in a manner similar to that shown in Fig. 5. Test mandrels shall conform to the dimensions in Table 5 or 5M and shall be hardened to not less than 55 HRC. The socket openings shall be gaged prior to testing. The tests shall be conducted after preheating the entire tool to a uniform temperature of 125°F (57.7°C), and the torque specified in the applicable table shall be applied within 1 min after removing the tool from the heating medium. The socket of the tool shall be inserted over the mandrel to the depth specified. The torque shall be applied and sustained for a mini- mum of 10 sec. The handle may be gripped in the area beyond the insertion distance of the socket shaft by suitable means. It shall be permissible to support the handle in order to maintain the tool in a suitable position for testing, provided the supporting means does not exert pressure end-wise during testing. Any cracking, failure of the socket opening to conform to the gaging requirement, or failure to sustain the proof torque for the prescribed time shall constitute failure. When tested to the minimum assembly torque value specified, the assembly shall not show a permanent slip- page between the shaft and handle. 5.2 Bending Moment Test Test shall be conducted in a manner similar to that shown in Fig.

6. Test mandrels shall conform to the dimensions in Table 6 or 6M and shall be hardened to not less than 55 HRC. A force of such magnitude to create the bending moment specified in the applicable table shall be applied at or near the middle of the natural grip of the handle for a minimum of 10 sec. The force is to act perpendicular to the axis of the tool. The tool shall not crack, break, or show any signs of visible per- manent set or looseness in the handle. The test shall be conducted at room temperature. 5.3 Solvent Tests Nutdrivers shall be capable of meeting the following test requirements. Handles are to be fully immersed in motor vehicle brake fluid (SAE J1703), gasoline, ethylene glycol, and ethyl alcohol for 15 minatroom temperature, removed, wiped off, and allowed to stand for 24 hr. ASME B107 pdf download.ASME B107-2004 pdf free download