ASME B107.100-2020 pdf free download.Flat Wrenches

4 CLASSIFICATION

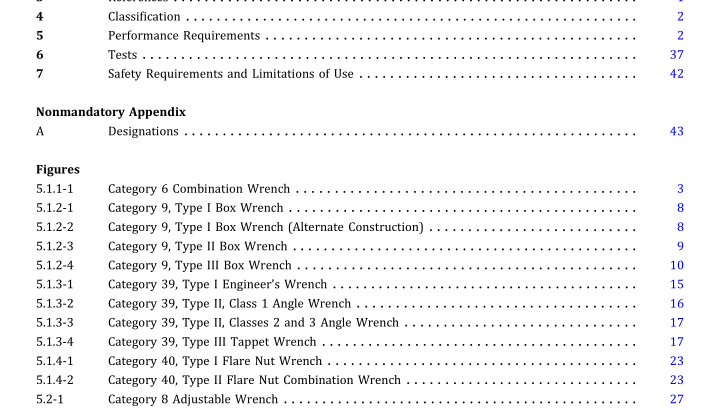

Categories, Types, and Classes of flat wrenches are shown in Table 4-1 and the applicable figures indicated therein.

5 PERFORMANCE REQUIREMENTS

The illustrations shown herein are descriptive and not restrictive; they are not intended to preclude the manu- facture ofwrenches thatare otherwise in accordance with this Standard.

Wrenches shall provide a well-proportioned comfor- table handgrip and be similar to the figure to which refer- ence is made.

The engaging surfaces of the wrench openings shall be finished in a smooth and well- defined manner. Wrenches shall pass applicable tests in section

6. Conformance with marking and other requirements not determined by test shall be verified by visual exam- ination.

When tested as specified, wrenches shall withstand the prooftorque specified in applicable tables withoutfailure or permanent deformation (set) that might affect the durability or serviceability of the wrenches. U.S. Customary table values are in inches unless other- wise specified. Metric table values are in millimeters unless otherwise specified. Wrenches shall meet the dimensional requirements in applicable tables.

5.1 Design — Categories 6, 9, 39, and 40

5.1.1 Category 6 — Combination Wrench.

Wrenches shall have one open end and one 15-deg offset box opening (Figure 5.1.1-1) and meet the requirements of Table 5.1.1-1 (Table 5.1.1-1M).

NOTE: Typical lengths are shown in Table 5.1.1-2 (Table 5.1.1-2M).

5.1.2 Category 9 — Box Wrench. Wrenches shall have two box ends (Figures 5.1.2-1 through 5.1.2-4) and meet the requirements of Table 5.1.2-1 (Table 5.1.2-1M). NOTE: Typical lengths are shown in Table 5.1.2-2 (Table 5.1.2-2M).

5.1.3 Category 39 — Open End Wrench. Wrenches shall have two open ends (Figures 5.1.3-1 through 5.1.3-4) and meet the requirements of Table 5.1.3-1 (Table 5.1.3-1M).

NOTE: Typical lengths are shown in Tables 5.1.3-2 through

5.1.3-5 (Tables 5.1.3-2M through Table 5.1.3-5M). 5.1.4 Category 40 — Flare Nut Wrench. Wrenches shall have two 6- or 12-point flare nut wrench ends of different sizes (Type I, Figure 5.1.4-1) or one open end and one end with a 6- or 12-point flare nut opening of identical nominal size (Type II, Figure 5.1.4-2) for use with hexagonal flare nuts. They shall meet the require- ments of Table 5.1.4-1 (Table 5.1.4-1M) or Table 5.1.4-2 (Table 5.1.4-2M), as applicable.

NOTE: Typical lengths are shown in Tables 5.1.4-3 and 5.1.4-4 (Tables 5.1.4-3M and 5.1.4-4M).

5.2 Design — Category 8: Adjustable Wrenches Adjustable wrenches shall consistessentiallyofa frame (fixed jaw and handle), a movable jaw, and a jaw opening adjustment mechanism (see Figure 5.2-1). When the wrench is in the full open position, the jaw shall extend to provide full contact across the flat hexagonal bar of a size that fits the full jaw opening specified for Type I wrenches (see Table 5.2-1).

The wrench shall be designed to allow free movement of the working parts. The wrench may be provided with or without a movable jaw-locking device.

5.2.1 Frame (Fixed Jaw and Handle). Means shall be provided in the wrench end ofthe frame for accepting the assembly of the movable jaw and adjusting mechanism. The handgrip end of the handle may be provided with a hole.

5.2.2 Movable Jaw. The movable jawshall be designed to permit free travel throughout the range of opening.

5.2.3 Adjusting Mechanism. The adjustingmechanism shallallowthemovablejawtobepositionedatanypointin its range and shall include means to hold the movable jaw in position.

5.3 Design — Category 21: Crowfoot Wrench Wrenches shall be designed to allow accessibility to fasteners in confined and restricted areas. The internal drive surfaces, and the nut and bolt head engaging surfaces of the flare nut and open end openings, shall be finished in a smooth and well-defined manner. The corners and/or serrations in the openings shall be clearly defined (not smeared or torn).

Type I wrenches shall be chamfered on both sides to provide a lead for the working surfaces. The slotted opening on Type I wrenches, and tips of all open ends on Type II wrenches, shall be chamfered or rounded to eliminate burrs.ASME B107.100 pdf download.ASME B107.100-2020 pdf free download