ASME B1.10M-2004 pdf free download.UNIFIED MINIATURE SIREW THREADS

1.5 Acceptability

Additional recommended methods for determiningthe acceptability of miniature screw threads will beincluded as further experience with this thread standardis reported.Until such time, agreements must be reachedbetween purchaser and vendor regarding the basis fordetermining acceptance, since practices are likely to dif-fer considerably, particularly for external threads. Wherea free choice is possible, the procedures given below,which are being used with considerable success by someproducers, are suggested.

1.5.1 External Threads.The major diameter of theexternal thread is measured by either contact gaging,optical projection,or laser inspection equipment. Allother dimensions,such as pitch diameter, lead, threadform, and minor diameter may be inspected by opticalprojection methods, with a magnification of 100x recom-mended. A suggested chart for this method is shownin Appendix A. The thread plug gages and the tap areinspected in a similar manner to externally threadedparts.Contact gaging, such as the use of “Go” andNOT Go” ring gages, measuring wires, and set pluggages may be used for sizes 0.70 UNM and above.

1.5.2 Internal Threads. The minor diameter of theinternal thread is gaged with“GO”and“NOT Go”plain cylindrical plug gages.All other elements arechecked only for assemble-ability limits by means of a“GO” thread plug gage, taking extreme care not to dam-age the thread. For the minimum material limits of theinternal threads, the accuracy and performance of thetap is relied upon. This implies that the major and pitchdiameters of the tap do not exceed the maximum inter-nal thread limits for these elements, and disregards overcutting, which is rarely incurred because of the flexibilityof these small taps and the manner in which they aregenerally fluted.

It is recommended that the minor diameter of theinternal thread be gaged with one insertion of the “NOTGO” plain cylindrical plug gage first.

The “NOT Go” plain cylindrical plug gage shall be inserted only until it meets some resistance. The minor diameter is then gaged with only one insertion of the plain cylindrical plug gage per thread, as the act of gaging can wear the thread oversize. At this point, the minor diameter is considered to be acceptable. The thread is gaged with only one insertion of the ” G O thread plug gage. The thread is accepted or rejected on the basis of this one insertion. Repeat insertions can wear out/damage the thread.

1.5.3 Reference Temperature. The reference tempera- ture is 20°C for the dimensions defined by this system.

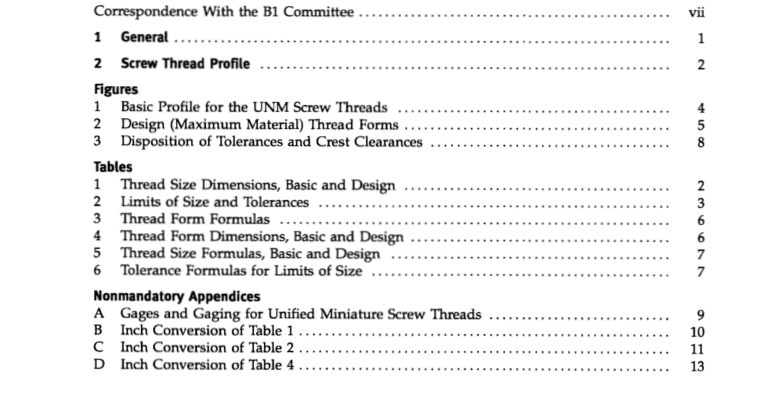

1.5.4 Units of Measure. All dimensions in this Stan- dard, including all tables, are in millimeters unless other- wise specified. Inch conversions may be found in Nonmandatory Appendices B, C, and D.

1.5.5 Federal Government Use. When this Standard is approved by the Department of Defense (DOD) and federal agencies, and is incorporated into FED-STD- H28 /5, Screw-Thread Standards for Federal Services, Section 5, the use of this Standard by federal government will be subject to ali requirements and Limitations of FED-STD-H28 /5.

2 SCREW THREAD PROFILE

2.1 Scope The basic profile and design profiles defined in this Section are the basis of all thread dimensions given in this Standard.

2.2 Basic Profile The basic profile for the UNM saew threads is shown in Fig. 1 (profile applies to the axial plane), and except for one element is the Unified Basic Thread Form. The exception is the height of thread engagement for which the basic value is 0.4800P. The basic thread height of 0.4800P (0.554H) will not affect interchangeability with products made to the 1958 revision of this Standard showing 0.5200P. As the resulting difference is negligible and completely ofíset by practical considerations in tapping, full internal thread heights are avoided in these small sizes to escape excessive tap breakage. For reference, the basic profile for UNM screw threads is identical to that for IC0 metric threads in ICO/R1501.ASME B1.10M pdf download.ASME B1.10M-2004 pdf free download