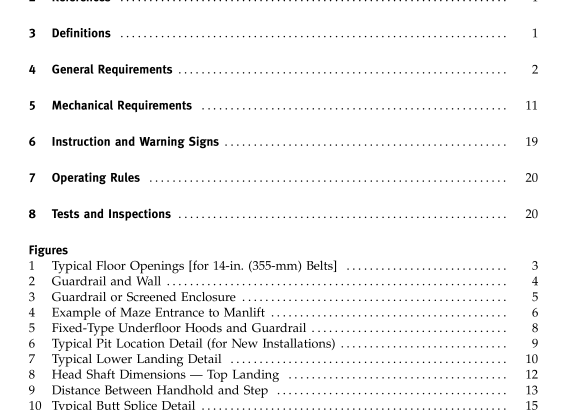

ASME A90.1-2015 pdf free download.Safety Standard for Belt Manlifts

4 GENERAL REQUIREMENTS

4.1 Floor Openings

4.1.1 Allowable Size. New installations shall have minimum floor openings of 30 in. (760 mm) and maxi- mum floor openings of 38 in. (965 mm). Floor opening widths for both the up- and down-runs for existing installations shall be in accordance with Table 1 and Fig. 1.

4.1.2 Uniformity. All floor openings for a given manlift shall be uniform in size and shall be approxi- mately circular, and each shall be located vertically above the opening below it.

4.2 Riding Clearance (a) There shall be no encroachment ofany kind within the cylindrical space defined by the outer edges of the floor openings for the entire run of the manlift. (b) Should maintenance or construction work be planned for in close proximity to the manlift causing an encroachment on the space defined in para. 4.2(a), the manlift shall be shut down during such work.

4.3 Landings

4.3.1 Vertical Clearance. The clearance between the floor or mounting platform and the lower edge for the underfloor hood above it required by para. 4.4 shall be not less than 7 ft 6 in. (2 285 mm). Where this clearance cannot be obtained, no access to the manlift shall be provided, and the manlift runway shall be enclosed where it passes through such floor. The enclosure shall be equipped with an emergency exit.

4.3.2 Clear Landing Space. The landing space adja- cent to the floor openings shall be free from obstruction and kept clear at all times. The landing space shall be at least 2 ft (610 mm) in width from at least one edge (one, two, or three) of the floor opening used for mount- ing and dismounting (see Fig. 2, 3, or 4 for typical land- ing spaces). 4.3.3 Lighting of Landings. Adequate lighting, not less than 5 fc (54 lx), shall be provided at each floor landing at all times when the lift is in operation.

4.3.4 Landing Surface. The landing surface at the entrances and exits to the manlift shall be constructed and maintained to provide safe footing at all times.

4.3.5 Emergency Landings. Where there is a travel of 50 ft (15 m) or more between floor landings, one or more emergency landing(s) shall be provided so that there is a landing (either floor or emergency) for every 25 ft (7.5 m) or less of manlift travel.

(a) Emergency landings shall be accessible from both the up- and down-runs of the manlift and shall give access to the ladder as required in para. 4.8.

(b) Emergency landings shall be provided with stan- dard railings and toeboards.

(c) Platforms constructed to give access to bucket ele- vators or other equipment for the purpose of inspection, lubrication, and repair may also serve as emergency landings under this paragraph. All such platforms shall then be considered part of the emergency landing and provided with standard railings and toeboards.

4.4 Hoods on Underside of Floor Openings

4.4.1 Fixed Type. On the up-side ofthe manliftfloor, openings shall be provided with an underfloor hood meeting the following requirements (see Fig. 5): (a) Slope. The underfloor hood shall make an angle of not less than 45 deg with the horizontal. (b) Extent. The lower edge of this hood shall extend at least 44 in. (1 118 mm) outward from the face of the belt. It shall not extend beyond the upper surface of the floor above. (c) Material and Construction. The hood shall be made of not less than No. 18 U.S. gage sheet steel or material of equivalent strength or stiffness. The lower edge shall have a minimum diameter of 1 ⁄ 2 in. (13 mm) and the interior shall be smooth with no protruding rivets, bolts, or screws.

4.4.2 FloatingType. Where the fixed hood specified in para. 4.4.1 is not used, a floating-type hood may be used; such floating hoods shall be mounted on hinges a maximum of 6 in. (150 mm) below and parallel to the underside of the floor, and so constructed as to actuate a safety switch that shuts off the manlift should a force of 2 lb (9 N) be applied on the edge of the hood closest to the hinge. The depth of this floating hood need not exceed 12 in. (305 mm).ASME A90.1 pdf download.ASME A90.1-2015 pdf free download