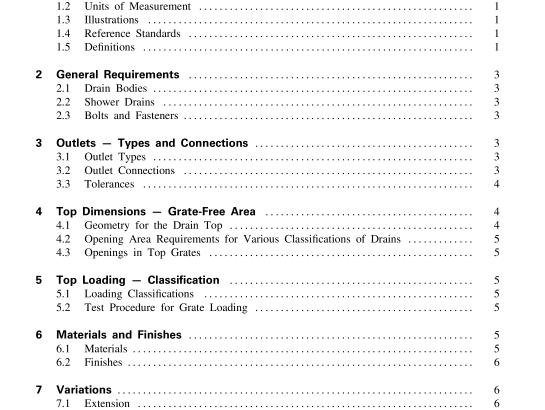

ASME A112.6.3-2001 pdf free download.FLOOR AND TRENCH DRAINS

2 GENERAL REQUIREMENTS

2.1 Drain Bodies

2.1.1 Materials. Drain bodies shall be of cast iron, copper alloy, ABS, PVC, PE, PP, or other approved materials meeting the requirements of this Standard. Materials shall comply with the standards cited in para. 1.4. No obstruction shall be permitted in the caulking area of a body.

2.1.2 Weep Holes. Weep holes in bodies shall be a minimum of three in number and shall be a minimum of 0.125 in. (3.2 mm) in diameter.

2.1.3 Smooth Mating Surfaces. The body and clamping ring shall have smooth, level surfaces to provide a watertight joint with the membrane.

2.2 Shower Drains 2.2.1 Strainers. Shower drain strainers shall be stainless steel 300 series alloy with a minimum thickness of 0.050 in. (1.3 mm). The strainer shall be of the snap-on type or screw fastened. The minimum waterway area of strainers shall be equal to the area of a 2 in. pipe [3.1416 in. 2 (2 027 mm 2 )]. 2.2.2 Crown/Collar. A 24 gauge corrosion-resis- tant crown and/or collar of 1 ⁄ 4 in. brass ring shall be required between the strainer and cast iron bodies.

2.3 Bolts and Fasteners Bolts and fasteners for cast iron or copper alloy drains shall be a minimum of 5 ⁄ 16 in. NC. Bolts and fasteners for plastic drains shall be a minimum of 1 ⁄ 4 in. NC. A minimum of three bolts per drain shall be provided. Screw and bolts provided for shower drains shall be 300 series stainless steel or copper alloy complying with ASTM B 584 (Alloy C 85200 or C 85400) or ASTM B 16.

3 OUTLETS — TYPES AND CONNECTIONS

3.1 Outlet Types

3.1.1 Bottom Outlet. Threaded, inside caulk, spigot, hubless, or solvent-welded with centerline of outlet vertical. (See Fig. 6.)

3.1.2 Side Outlet. Threaded, hub (outside caulk), spigot, hubless, or solvent-welded with centerline of outlet horizontal. (See Fig. 7.)

3.1.3 Side Outlet With Integral Trap. Threaded, hub (outside caulk), spigot, hubless or solvent-welded with centerline of outlet horizontal, and with P trap integral with drain body sump. (See Fig. 8.)

3.2 Outlet Connections 3.2.1 Threaded. All threaded outlet connections shall be American Standard Taper Pipe Threads for general use (NPT) and shall conform to the minimum dimensions shown in Table 1.

3.2.2 Inside Caulk. All inside caulk outlet connec- tions shall conform to the minimum dimensions shown in Table 2. No obstructions shall be permitted in the caulking areas.

3.2.3 Hub (Outside Caulk). All hub connections shall conform to the minimum dimensions shown in Table 3.

3.2.4 Spigot. All spigot outlet connections shall conform to the beadless dimensions shown in ASTM A 74 or ASTM A 888.

3.2.5 Solvent Cement. All solvent-cemented out- let connections shall be made using appropriate solvent cement and methods of joining. ABS solvent cement joints shall be in accordance with ASTM D 2661 and PVC solvent cement joints shall be in accordance with ASTM D 2665.

3.2.6 O-ring or Gasketed Joints. O-ring or gas- keted joints shall comply with ASTM C 564, ASTM C 1440, or CSA B602.

3.3 Tolerances

Dimensions given in Tables 1, 2, and 3 and the associated figures shall be subject to standard commer cial tolerances of ± 1 ⁄16 in. (± 1.6 mm).

4 TOP DIMENSIONS — GRATE-FREE AREA

4.1 Geometry for the Drain Top

The drain top shall be any geometric shape.

4.2 Open Area Requirements for Various Classifications of Drains Opening area requirements for drains shall be as shown in Table

4. 4.3 Openings in Top Grates Openings shall be any geometric shape. Openings shall be sized to exclude debris and accommodate the anticipated traffic. When drainage requirements dictate openings that would permit entrance of debris, a sedi- ment bucket shall be installed in the drain body sump to intercept this debris. 5 TOP LOADING — CLASSIFICATION

5.1 Loading Classifications Grates and top rims shall be designed to meet the following loading classifications:

5.1.1 Light Duty. Grates having safe live load (as calculated in para. 5.2.5) under 2,000 lb (900 kg).

5.1.2 Medium Duty. Grates having safe live load (as calculated in para. 5.2.5) between 2,000 lb (900 kg) and 4,999 lb (2 250 kg).ASME A112.6.3 pdf download.ASME A112.6.3-2001 pdf free download