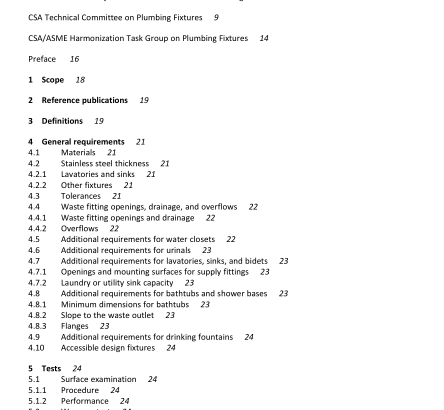

ASME A112.3-2017 pdf free download.Stainless steel plumbing fixtures

4.6 Additional requirements for urinals Urinals and their flushing devices shall comply with the applicable requirements of ASME A112.19.2/ CSA B45.1, except that the

a) structural integrity test shall be conducted in accordance with Clause 5.5.3; and

b) minimum thickness requirements for vitreous china shall not apply. 4.7 Additional requirements for lavatories, sinks, and bidets

4.7.1 Openings and mounting surfaces for supply fittings

4.7.1.1 When provided, openings and mounting surfaces for lavatory, sink, and bidet supply fittings shall be as shown in Figures 2 to 6, except when proprietary (i.e., non-standard) supply fittings are provided by the manufacturer.

4.7.1.2 Factory-supplied lavatory, sink, and bidet supply fittings shall comply with ASME A112.18.1/CSA B125.1.

4.7.1.3 Mounting surfaces for supply fittings that rely on an air gap for backflow protection shall be not more than 13 mm (0.5 in) below the flood level rim. Note: Care should be taken to ensure that the minimum air gap specified in ASME A112.18.1/CSA B125.1 or in the applicable plumbing code is not compromised when supply fittings are installed on fixtures with mounting surfaces below the flood level rim.

4.7.2 Laundry or utility sink capacity The minimum capacity of at least one compartment of a laundry or utility sink shall be 60 L (15.9 gal).

4.8 Additional requirements for bathtubs and shower bases

4.8.1 Minimum dimensions for bathtubs The minimum dimensions for bathtubs shall be as shown in Figure 7.

4.8.2 Slope to the waste outlet Bathtubs and shower bases shall have a maximum slope of 4% to the waste outlet. Note: There should be a minimum slope of 1% to the waste outlet.

4.8.3 Flanges Bathtubs and shower bases intended for installation against a wall shall incorporate a flange raised at least 8 mm (0.3 in) above the rim. The flange shall be

a) integral with the bathtub or shower base;

b) added to an island tub or shower base in the factory; or

c) field installed using a flange kit that complies with Clause 5.3 and includes all necessary parts and fasteners. Fixtures using field-installed flanges shall be marked in accordance with Clause 6.4.

4.9 Additional requirements for drinking fountains

4.9.1 Drinking fountains shall a) include a supply fitting, which shall be at least 25 mm (1.0 in) above the flood level rim; and b) comply with the dimensions shown in Figure 8. Note: Drinking fountain supply fittings are also known as drinking fountain bubblers.

4.9.2 Factory-supplied drinking fountain supply fittings shall comply with ASME A112.18.1/CSA B125.1, including the toxicity requirements.

4.10 Accessible design fixtures Fixtures designed to be accessible shall comply with the dimensional requirements specified in CSA B651 or ICC/ANSI A117.1. 5 Tests 5.1 Surface examination 5.1.1 Procedure Visible surfaces shall be examined for defects by the unaided eye under ordinary light at a distance of approximately 610 mm (2 ft). Note: Unaided eye includes vision assisted by corrective lenses normally worn by the person inspecting the specimen.

5.1.2 Performance Visible surfaces shall be free of blemishes, cracks, die marks, pinholes, and wrinkles. Surface details that are part of the design shall not be cause for rejection.

5.2 Warpage test

5.2.1 Procedure The specimen shall be placed on a flat and level surface to ascertain the amount of deviation from the horizontal plane that exists at its edges. A feeler gauge of a thickness equal to the total warpage allowed in Clause

5.2.2 shall not slide under the specimen unless forced. If the specimen rocks on two opposite corners, the horizontal plane shall be determined by placing one feeler gauge, as thick as the total warpage allowed, under a corner that does not touch the flat and level surface. This gauge is inserted by not more than 1/16 in.Forcing the specimen down on this gauge, a second feeler gauge of the same thickness shall not slide under the specimen at any other point.ASME A112.3 pdf download.ASME A112.3-2017 pdf free download