ASME B16.20a-2000 pdf free download.METALLIC GASKETS FOR PIPE FLANGES Ring-Joint, Spiral-Wound, and Jacketed

2.7 ldentification Number

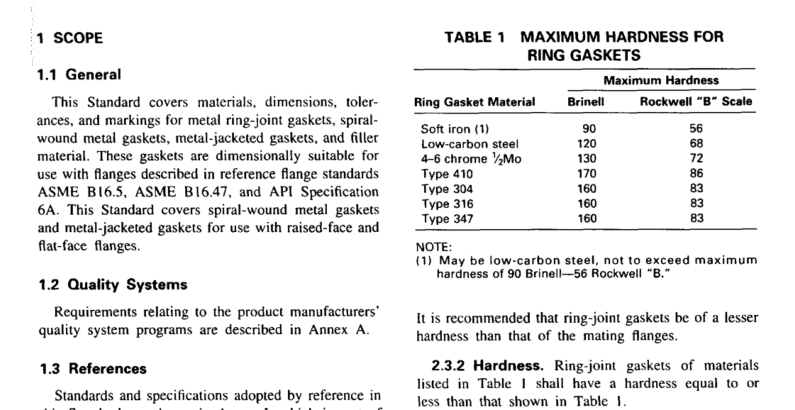

Dimensional reference identification numbers are as-signed to ring-joint gaskets and are shown in Tables3 through 8.

3 SPIRAL-WouND GASKETS3.1 Size and Class

Spiral-wound gaskets. including centering ring andinner ring (paras. 3.2.4 and 3.2.5). are identified byflange size (NPS). pressure class. and the appropriatcflange standard (ASME Bl6.5 or ASME Bi6.47).3.2 Dimensions and Tolerances

3.2.1 General. Dimensions and tolerances for spi-ral-wound gaskets. centering rings. and inner rings shallbe in accordance with Tables 9 through l! and asspecified in this section.

3.2.2 Construction. Spiral-wound gaskets shall bcconstructed as altemnatc plies (circular layers countedas revolutions) of preformcd mctal windings and plaintfillers that are spirally wound. For the finished gasket,the filler shall be essentially flush with. but not below,the metal winding on both contact faces of the gasket.The metal strip in the winding shall be 0.006 in. to0.009 in. thick. The filler material thickness shall bedetermined by the manufacturer.

3.2.3 Metal Joining. The inner windings shallhave a minimum of three plies of preformcd metalstrip without filler. The initial two plies shall be spot-weided circumferentially with a iminimum of threewclds spaced at a maximum distance of 3 in. The outcr winclings. which shall have a minimum of threeplies of preformed metal without filler,shall be spot-welded circumferentially with a minimum of threewelds. the last of which shall be the terminal weld.The distance of the first weld from the terminal weldshall be no greater than 1.5 in. Up to four additionalloosc preformed metal windings beyond thc terminalweld may be used to retain the gasket into the center-ing ring.

3.2.4 Centering Ring. All spiral-wound gaskctsshall be furnished assembled into a centering ring. Theccntering ring thickness shall be from 0.117 in. to0.131 in. and suitably grooved on the inside diameterso as to retain thc gaskct.

3.2.5 Inner Ring. Inner rings shall be furnishedwith all spiral-wound gaskets having PTFE (polytetra-fluoroethylene) filler material. It is recommended thatinncr rings bc specificd by thc uscr for flcxiblc graphiteand other filler materials (if appropriate for flanges andbore sizes used), particularly where experience hasdemoonstrated inward buckling of the gaskets to be aproblem. Inner rings shall be furnished in spiral-woundgaskets for flanges NPS 24 and larger in Class 900,NPS 12 and larger in Class 1500. and NPS 4 andlarger in Class 2500.Gaskets with inner rings shouldbeused only with socket welding, lapped,weldingneck. and integral flanges.

The inner-ring thickness shalt be from 0.1 17 in. to0.131 in. Tables 12 through l4 show inner-ring insidediamctcrs that may extend a maximum of 0.06 in. intothe flange bore under the worst combination of flangebore. eccentric installation, and tolerance. ReferenceTable 15 for minimum pipe wall thickness for use withgaskets with inner rings. Reference Tables 16,17,and18 for maximum allowable borc for use with gasketswithout inner rings.

3.2.6 Gasket Compression. Spiral-wound gasketsNPS 2.NPS 3/. and NPS 1 in Classes 150,300,and60O shall be designed so that a uniform bolt stress of25.000 psi、bascd on thc nominal bolt root diameter,will compress the gasket to a thickness of 0.130 in.工O.005 in. All other gasket sizes and classes shall be designed so that a uniform bolt stress of 30,000 psiwill compress the gasket to a thickness of 0.130 in.士0.0M05 in.

3.3 Materials

Metal windings and tiller materials shall be in accord-ance with Table 19.ASME B16.20a pdf download.ASME B16.20a-2000 pdf free downloadASME B16.20a-2000 pdf free download