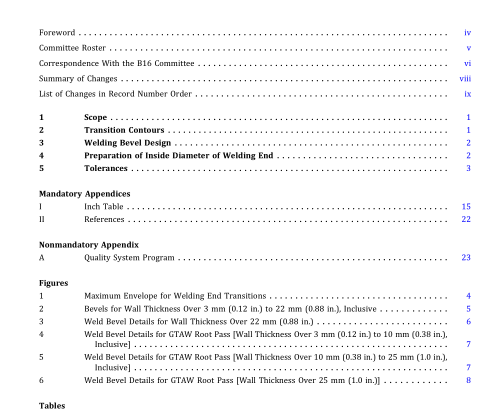

ASME B16.25-2017 pdf free download.Buttwelding Ends

1.5 Referenced Standards Standards and specifications adopted by reference in this Standard are shown in Mandatory Appendix II. It is not considered practical to identify the specific editionofeachstandardandspecificationintheindividual references. Instead, the specific edition reference is iden- tifiedinMandatoryAppendixII. Aproductmadeinconfor- mance with a prioredition ofreferenced standards will be considered to be in conformance, even though the edition reference may be changed in a subsequent revision ofthe standard.

1.6 Quality Systems Nonmandatory requirements relating to the manufac- turer’s quality system program are described in Nonmandatory Appendix A.

1.7 Convention For determining conformance with this Standard, the convention for fixing significant digits where limits (maximum and minimum values) are specified shall be as defined in ASTM E29. This requires that an observed orcalculatedvalueberoundedofftothenearestunitinthe lastright-hand digitused forexpressingthe limit. Decimal values and tolerances do notimply a particular method of measurement.

2 TRANSITION CONTOURS

Figure 1 delineates the maximum envelope in which transitions from welding bevel to the outer surface of the component and from the root face to the inner surface of the component must lie. Except as specified in Note (5) to Figure 1, and as otherwise specified by the purchaser, the exact contour within this envelope is the manufacturer’s option, provided it maintains the specified minimum wall thickness, has no slopes steeper than those indicated for the respective regions, and includes the proper surface for backing rings if specified.

3 WELDING BEVEL DESIGN

3.1 Bevels for Other Than GTAW Root Pass (a) Components having nominal wall thicknesses of 3 mm (0.12 in.) and less shall have ends cut square or slightly chamfered. (b) Components having nominal wall thicknesses over 3 mm (0.12 in.) to 22 mm (0.88 in.) inclusive shall have single angle bevels as illustrated in Figure 2. (c) Components having nominal wall thicknesses greater than 22 mm (0.88 in.) shall have compound angle bevels as illustrated in Figure 3.

3.2 Bevels for GTAW Root Pass (a) Components having nominal wall thicknesses of 3 mm (0.12 in.) and less shall have ends cut square or slightly chamfered. (b) Components having nominal wall thicknesses over 3 mm (0.12 in.) to 10 mm (0.38 in.) inclusive shall have 37 1 ∕ 2 -deg ± 2 1 ∕ 2 -deg bevels or slightly concave bevels (see Figure 4). (c) Components having nominal wall thicknesses over 10 mm (0.38 in.) to 25 mm (1.0 in.) inclusive shall have bevels as shown in Figure 5. (d) Components having nominal wall thicknesses greater than 25 mm (1.0 in.) shall have bevels as shown in Figure 6. 3.3 Outside Diameter at Welding Ends Dimension A shall be either that specified in the applic- able component standard or that specified in the purcha- ser’s component specification. In the absence of a requirement for dimension A in a component standard or a purchaser’s specification, the values for dimension A in Table 1 or Table I-1 may be used.

4 PREPARATION OF INSIDE DIAMETER OF WELDING END

4.1 General Preparation of the inside diameter at the end of a component shall be in accordance with one of the following, as specified by the purchaser: (a) Components to be welded without backing rings shall meet the requirements ofthe standard or specifica- tion for the component. (b) Components to be welded using splitor noncontin- uous backing rings shall be contoured with a cylindrical surfaceattheendas showninFigure2,illustration(b) and Figure 3, illustration (b). If the backing ring contour is other than rectangular, details must be furnished by the purchaser. (c) Components to be welded usingsolid orcontinuous backing rings shall be contoured with a cylindrical or tapered surface at the end as specified by the purchaser. End preparation is illustrated in Figure 2, illustration (c) and Figure 3, illustration (c) for rectangular ends and in Figure 2, illustration (d) and Figure 3, illustration (d) for tapered ends. (d) Components to be welded using consumable insert rings or GTAW root pass shall be contoured with a cylin- drical surface at the end as shown in Figures 4 through 6.ASME B16.25 pdf download.ASME B16.25-2017 pdf free download