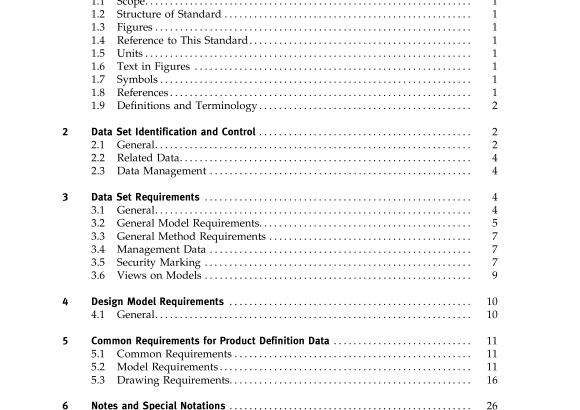

ASME Y14-41-2003 pdf free download.DIGITALPRODUCT DEFINITION DATA PRACTICES

4.1.1 Geometric Scale, Units, and Precision. The fol- lowing are the requirements concerning the Scale, Units, and Precision of a design model.

(a) Scale. Design models shall be modeled at a scale of 1:1.

(b) Units. The units ofmeasure (metric or U.S. custom- ary) at which the design model is created shall be speci- fied within the data set.

(c) Precision. The design model precision indicates the numeric accuracy required in the production of the part in order for it to fulfill the design intent. The number ofsignificantdigits ofthe designmodelshallbespecified in the data set. The number of decimal places required for the design cannot exceed the precision of the design model.

4.1.2 Model Completeness.

The model shall contain geometry, attributes, and annotation as required to pro- vide a complete definition of the part.

(a) Models not fully modeled shall be identified as such (e.g., partially modeled symmetrical part). (b) Features that are not fully modeled shall be identi- fied as such (e.g., threaded holes that are only shown as holes).

4.1.3 Assembly Model Completeness. Assembly model completeness shall be in accordance with para. 4.1.2, except part and sub-assembly models shown in the assembly model need only have sufficient detail shown to ensure correct identification, orientation, and placement. The assembly model may be shown in an exploded, partially assembled, or completely assembled state. The placement of parts and sub-assemblies within the assembly may alternatively be defined via annota- tion, or a combination of annotation and pictorial repre- sentation of the model.

4.1.4 Installation Model Completeness. Installation completeness shall be in accordance with paras.

4.1.2 and 4.1.3, except part and assembly models shown in the installation model need only be sufficiently detailed to provideinstallationandspacerequirements. The max- imum envelope for parts and assemblies may be shown usingsupplemental geometry, annotation, or a combina- tion of both. Location and orientation of parts and assemblies may be shownby geometric definition, anno- tation, or a combination of both.

5 COMMON REQUIREMENTS FOR PRODUCT DEFINITION DATA

This Section establishes the common requirements for the application, display management, and query of productdefinition data. Specific requirements forpartic- ular types of product definition data are described in Sections 6 through 10.

5.1 Common Requirements

The following paragraphs describe requirements common to models and drawings.

5.1.1 Display Management. Display management shall include the ability to enable or disable the display of all annotation, annotation by type, or selected annota- tion. See Fig. 5-1.

5.1.2 Hard Copy. A hard copy of any given visual display shall be available on demand. When a hard copy is intended to be used as an engineering drawing, it shall meet applicable drawing standards.

5.2 Model Requirements

The following paragraphs describe requirements for annotation applied to a design model. These are general requirements that apply to all types of annotation. Spe- cific requirements for particular types of annotation are addressed in Sections 6 through 10. See Fig. 5-2 for a diagram showing the relationship between annotation and model geometry.

5.2.1 Associativity.

The following are general re- quirements for defining an associative relationship be- tween digital elements.

(a) Selection ofAssociated Entities. Annotation may be associated to a feature, a group of features, or a portion ofanapplicable feature. For anexample ofthe associated features for a dimension, see Fig. 5-3.

(b) Associated Groups. Annotation, model geometry, and supplemental geometry may be placed into associ- ated groups to indicate their relationships. For example:

(1) Supplemental geometry used to define location, orientation, or further clarify the application of annota- tion to a model.

(2) A model coordinate system for datum symbols and datum targets.

(3) Other Annotation. This could include qualifying notes and size limit callouts.

5.2.2 Attributes. Attributes are used to capture addi- tional information that is not shown using geometry or in the model annotation. Attributes shall be available on demand. Attributes may be presented using text de- scription, forms, or other techniques. See Fig. 5-4 for an example of how the attributes of a hole could be represented. Applications of attributes include, but are not limited to, coatings, knurling, threaded holes, and pins.ASME Y14-41 pdf download.ASME Y14-41-2003 pdf free download